Change Language

The following languages are fully supported on our offering of international sites, including detailed product information and e-commerce functionality.

Additional regional languages may be available on your local Swagelok Sales and Service Center's websites.

Explore Swagelok Reference Point

Choose one of the categories below for a deeper dive into our wide range of resources.

Explore the Swagelok Fluid System Blog

The quality of Swagelok components tells one part of our story. The other part? The successes we help our customers achieve by sharing our deep and varied knowledge across industries and applications.

Browse our blog content by selecting a category below.

Analytical Instrumentation

Why You Should Not Intermix Tube Fittings

Learn why intermixing and interchanging tube fittings and tube fitting components from different manufacturers can lead to potentially poor performance in your industrial fluid or analytical instrumentation system.

Improve Safety and Efficiency in Liquid Grab Sampling

Learn about safe and effective liquid grab sampling techniques, as well as ideal design characteristics to seek out when selecting and specifying your systems and panels.

Know Your Process Analyzers: Raman Analyzers

Learn about Raman process analyzers, including their advantages and ideal applications, and why accurate process analysis can help you reduce off-spec products.

How to Troubleshoot Common Regulator Problems

Pressure regulator malfunction and failure impact your facility’s productivity and safety. Learn how to troubleshoot common issues with back-pressure regulators and pressure-reducing regulators.

Why Fluid System Filters Are Critical for Reliable Operations

Learn about the basics of fluid system filters and gas and liquid filtration as well as how you can apply them to your systems to protect critical components and optimal outcomes.

Tips for Safe, Accurate Gas Grab Sampling

Read about common challenges associated with volatile liquid and gas grab sampling and learn to overcome them by using the right techniques and appropriate equipment.

Small Footprint, Large Impact: How to Detect and Protect Against Gauge Failures

Learn to recognize the signs of a failing gauge and avoid risk to employees and costly downtime to make repairs.

How INEOS Achieves Analytical Instrumentation Precision

INEOS depends on analytical accuracy to serve its global customers with high-quality chemical products. Learn why the company trusts Swagelok for quality instrumentation system components, service, and training.

Our Most Popular Blogs in 2021

Read our most popular blog posts of 2021, which cover your most pressing challenges, from corrosion control to fitting selection to material specification.

Analyzing Your Sampling Needs

Trying to determine whether grab sampling or online analysis is the best option to monitor your process conditions? We put together a convenient checklist to help guide you to a solution that suits your operations.

How to Reduce Emissions at Sampling Points

As refineries, chemical plants, and other facilities seek new ways to reduce fugitive emissions, one strategy can be relatively simply and cost-effective: specifying closed-loop sampling systems.

How to Flatten a Regulator Flow Curve to Reduce Droop

Droop is an issue for every pressure-reducing regulator. Learn how to minimize droop and flatten regulator flow curves with various dome loaded regulator configurations explained by Jon Kestner.

Why Safe Industrial Pressure Regulator Performance Requires Rigorous Testing

Learn why robust pressure regulator testing can help verify proof of performance under the most strenuous, real-world industrial fluid system applications.

Back-Pressure Regulator Set-Up: Tips for Sampling System Engineers

Back-pressure regulators can effectively control upstream pressure within a sampling system process line—when set up correctly. Learn how to accurately design and build a process line with a back-pressure regulator.

How to Use a Regulator to Reduce Time Delay in an Analytical Instrumentation System

Time delay is often underestimated or misunderstood in analytical systems. One way to mitigate this delay is with a pressure-controlled regulator. Learn how manage your analytical system’s time delay with tips from the experts at Swagelok.

Shaping the Future with Reliable Microreactors

Learn how German microreactor producer Ehrfeld Mikrotechnik uses Swagelok components to make important connections in cutting-edge laboratory applications around the world.

Improving Lab Safety and Productivity

Learn why optimized gas distribution systems are critical for maintaining the safety and productivity of laboratories.

Managing Supply Pressure Effect (SPE) in a Regulator

Supply pressure effect, also known as dependency, is an inverse relationship between inlet and outlet pressure variables within a regulator. Learn how to manage this phenomenon in your pressure regulators with tips from Swagelok.

3 Rules for Analyzer Accuracy

Learn to avoid three common sampling system performance problems that can lead to analyzer inaccuracies, costing you time and money.

4 Areas to Inspect When Measuring Time Delay in Sampling Systems

In a process analyzer sampling system, there is always a time delay before you obtain a reading. However, underestimating this time delay can lead to inferior process control. Learn which four areas you should closely inspect to diminish time delays.

Tips to Maintaining a Representative Sample in an Analytical Instrumentation System

Maintaining a representative sample within an analytical instrumentation system can be difficult. Learn how to identify major issues and avoid complications associated with a compromised representative sample from the experts at Swagelok.

How to Calibrate an Analyzer in an Analytical Instrumentation System

Calibration is an important process and an absolute requirement in analytical systems. Care must be taken when performing this process—error can be introduced. Learn how to calibrate your analyzer to ensure an accurate analytical measurement.

Understanding and Measuring Time Delay in an Analytical Instrumentation System

Process measurements are instantaneous, but analyzer responses are not. Time delay in sampling systems is the most common cause of inaccurate results from process analyzers. Learn how to understand and reduce time delay in your analytical systems.

Sampling Systems: 8 Common Process Analyzer Accuracy Challenges

Sampling systems expert and veteran industry instructor Tony Waters offers plant managers and design engineers tested ways to identify and resolve 8 common challenges for process analyzer accuracy.

5 Common Process Analyzer System Revelations over 50 Years of Training

Sampling systems can be one of the most challenging systems within your plant to both design and operate. Industry veteran and industrial training instructor, Tony Waters, shares his trainees’ top revelations over the past 50 years.

10 Tips to Improve Sampling Systems

Managing an analytical instrumentation operation is no small feat. Receiving consistent results can be a struggle for even the most seasoned engineers. Luckily, there are several simple tips your team can use to improve your sampling system.

Chemicals

How to Decarbonize and Cut Fugitive Emissions

Refineries and oil and gas facilities face an increasing need to reduce fugitive emissions throughout their facility. Learn the driving factors behind decarbonization and fugitive emissions reduction and strategies to do it.

How to Achieve Safer, More Accurate, and More Efficient Ammonia Sampling

Learn how pre-engineered ammonia sampling systems can take away some of the complexity and inherent risks involved with manual ammonia sampling practices.

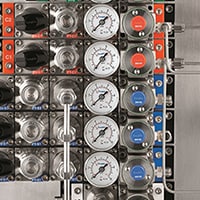

Improve Gas Distribution Safety and Efficiency

Gas distribution systems are crucial for helping labs, test centers, and industrial facilities operate at peak efficiency. Learn more about optimizing gas delivery system health and safety, reducing costs, and equipping your team for success.

Seven Tips for Effective Plant Turnarounds

A plant turnaround can be a big headache for a chemical plant or refinery—but it doesn’t have to be. Learn seven strategies for more effective turnaround management.

Why Relief Valves Are Essential for Chemical Plant Safety

Learn how to improve chemical plant safety and protect sensitive equipment by designing relief valves into critical applications to prevent potentially dangerous overpressurization.

How to Fix Common Grab Sampling Deficiencies

There are several common fluid systems that successful plant operation depends on and outsourcing their fabrication can be highly beneficial if you are short on resources.

Q&A: How to Optimize Your Gas Distribution System

Learn about common challenges that can hamper the safety and efficiency of important gas distribution systems and how a professional evaluation of those systems can provide long-term value.

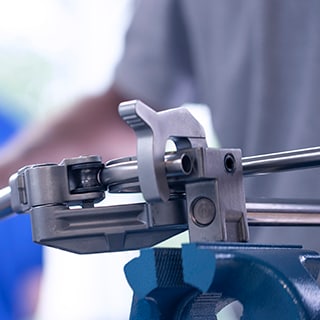

Building Better Mechanical Seal Support Systems

Learn how API 682 guides the design and assembly of mechanical seal support systems and how applying a few best practices can help your systems last longer and work better.

Choosing the Right Type of Pressure Regulator for Your Application

Learn how to match the right type of industrial pressure regulator to specialized applications, helping you best maintain process conditions to improve operational safety and efficiency.

How INEOS Achieves Analytical Instrumentation Precision

INEOS depends on analytical accuracy to serve its global customers with high-quality chemical products. Learn why the company trusts Swagelok for quality instrumentation system components, service, and training.

Sample Cylinder Maintenance FAQ: What You Should Know

Learn about the importance of sample cylinder maintenance for safe operations and what it takes to develop a proactive maintenance program.

How to Reduce Costly Leaks and Emissions in Your Facility

Leaks can cause trouble in any process-driven industrial facility. Learn how to reduce common costly fluid system leaks, including fugitive emissions, with the right high-quality products and services.

An Introduction to Grab Sampling

Learn about grab sampling best practices for both gaseous and liquid fluid system media, the characteristics of well-designed and easily operable grab sampling systems, and how to reliably achieve grab sampling accuracy.

Shaping the Future with Reliable Microreactors

Learn how German microreactor producer Ehrfeld Mikrotechnik uses Swagelok components to make important connections in cutting-edge laboratory applications around the world.

How Consistent Grab Sampling Enables Ongoing Innovation for a Leading Refrigerant Producer

Refrigerant and fluoropolymer production requires adherence to strict quality control measures and safety protocols. Learn how one leading manufacturer stays ahead of the competition with Swagelok grab sampling solutions.

Cut Maintenance Costs with Enhanced Gas Panels

Learn how easy-to-use gas panels and an overall more efficient gas distribution and delivery system can help laboratories, refineries, and other facilities drive down maintenance costs.

Liquid Grab Sampling Strategies to Control Costs

Discover several strategies to help drive down costs and minimize errors in your liquid grab sampling processes as you validate process conditions and analyze end product quality.

Inventory and Innovation at a Carbon Capture Company

Learn how LanzaTech, a carbon capture technology company, stays ahead of shifting customer needs and continuously innovates with high quality products, services, and inventory solutions from Swagelok.

Field Engineering Spotlight: Trey Sinkfield

Swagelok field engineers work to help customers solve tough fluid system challenges. Hear from Swagelok Southeast Texas’ Trey Sinkfield on why he loves working collaboratively with customers to find effective fluid system solutions.

Identifying Cost Savings in Utility Gas Systems

See how Swagelok Texas Mid-Coast provided on-site analyses of a major petrochemical producer’s aging utility gas system and uncovered savings of more than $2 million annually.

Tackling Global Engineering Complexity for a Successful Megaproject

Swagelok’s Global Construction team worked closely with dozens of global engineering firms to complete a massive petrochemical megaproject in Southeast Asia. Learn about the keys to this successful project.

Industrial Virtual Visits: A New Form of “On-Site Experience”

Learn how Swagelok is adopting virtual headset technology to provide real-time troubleshooting, fluid system evaluation services, and more to customers when in-person visits are difficult to arrange.

Analytical Sampling Systems Q&A

Swagelok Field Engineering Manager Mike Frost answers questions on common analytical sampling system problems.

Five Considerations for Your Analyzer Shelter

Analyzer shelters are an important part of any industrial refinery or other oil and gas facility. Learn some fluid and sampling system concerns to think about from Swagelok.

Do’s and Don’ts for Sampling System Accuracy

Follow these do’s and don’ts to obtain more accurate, representative samples from your industrial sampling system.

Refinery Safety Depends on Well-Trained, Empowered Employees

Fugitive emissions of hazardous gases can occur in refineries. Safe, leak-free containment depends on knowledgeable and empowered teams.

Why Haven’t Sampling Systems Improved — Three Main Reasons

Over the past 50 years, process analyzers have vastly improved— but sampling systems have not. Luckily, most issues are due to human error & can be corrected with proper training. Learn three reasons why sampling systems fail & solutions for your plant.

Grab Sampling 101: Reducing Plant Costs

Grab sample systems allow for safe, efficient sample captures—validating your product’s chemical composition. Learn how to improve your closed loop system’s reliability while reducing plant costs with basics from the experts at Swagelok.

Common Challenges with Process Sampling Systems

Sampling system experts and industry veterans, Tony Waters and Phil Harris, share some common challenges they have encountered with process analyzer sampling systems over the years. Learn how to resolve recurring issues within your sampling system.

Calculating the ROI of Process Analyzer Technology

Process analyzers are a costly, but necessary, sampling system expenditure. When justifying this expense, it’s important that you accurately calculate the analyzer’s ROI. Learn how to determine ROI and save your plant money with tips from Swagelok.

INEOS Petrochemical Safety Case Study

Swagelok’s contribution to the safe operation of INEOS’s petrochemical facility in Cologne, Germany maps back to the close collaboration between the two companies. Learn how Swagelok’s trusted reliability helps INEOS ensure petrochemical safety.

Clean Energy

Ensuring Hydrogen Purity for Fuel Cells

Gain expert knowledge from the white paper author regarding hydrogen purity for PEM fuel cells. Explore key insights on hydrogen fuel quality, sampling methodologies, and international standards.

Ask Swagelok: Hydrogen, Sampling and Corrosion Insights

Explore expert insights on fluid systems with Swagelok's video series. Topics include hydrogen design and embrittlement, offshore corrosion, liquid sampling and more.

Top 5 Hydrogen Design Best Practices

As one of the most promising sources of clean energy, hydrogen is important—but building fluid systems to handle it requires specific knowledge and expertise. Learn critical, practical tips for designing hydrogen systems.

Hydrogen: A Truly Sustainable Alternative Fuel

Have questions about the sustainability profile of hydrogen fuel? We have answers—learn more about hydrogen production and the fuel’s potential as a viable, sustainable power source.

Why Hydrogen Is a Cost-Effective Fuel

Is hydrogen too expensive for mass adoption as an alternative fuel? The answer is simple: No. Learn why hydrogen fuel prices continue to fall, making it a viable alternative to fossil fuels.

Have Hydrogen Vehicle Range Anxiety? Here’s Why You Shouldn’t.

Do hydrogen fuel cell vehicles have what it takes to travel comparable ranges to gasoline or diesel vehicles? We have the facts. Learn why hydrogen is a viable fuel for longer-range travel.

Is Hydrogen a Safe Fuel Source?

Hydrogen has the potential to be a revolutionary clean energy source, but some common myths abound about the fuel’s safety. Get the facts about hydrogen as we explore why it’s a safer fuel source than conventional options.

FAQs: How to Avoid Hydrogen Embrittlement

Selecting the right materials for hydrogen-handling applications is critical to the long-term viability of hydrogen as a fuel source. Learn how to select the right materials and prevent hydrogen embrittlement.

Measuring and Controlling Hydrogen Flow

See how an automotive testing and simulation company partnered with Swagelok to transition to hydrogen fuels technology.

Optimize Your Electrolyzers With Fluid System Support

The hydrogen electrolysis process depends on reliable inflow and outflow fluid systems. Learn how you can control costs, enhance safety, and maximize productivity with the right fluid system support.

Your Top Five Questions of 2022

Find answers to some of the most common questions we received throughout 2022, reflected in the most popular Swagelok Reference Point posts of the year. We cover droop in flow curves, industrial hose best practices, and more.

Safe, Reliable Hydrogen Handling: Find Out What It Takes

Hydrogen mobility requires the highest-quality components to meet the technology’s full potential. Here’s what you need to know to develop safe, reliable, and long-term hydrogen transportation solutions.

Supporting the Production and Storage of Green Hydrogen

See how Everfuel is making hydrogen happen with the help of Swagelok products and expertise.

What to Look for in Hydrogen Valves

Valves are critical parts of hydrogen fluid systems. Learn what to look for in an ideal hydrogen valve and how it can contribute to safer, more reliable hydrogen transportation.

Building Safe and Reliable Hydrogen Refueling Stations

Learn how a leading hydrogen refueling station and onboard fuel system manufacturer in China is keeping pace with the rapidly evolving hydrogen transportation market with help from Swagelok.

Building CNG Buses, Refueling Stations with Swagelok

Learn why one major CNG bus OEM relies on Swagelok for reliable service, training, and quality components that are designed to meet the demands modern transportation service requires.

Busting Hydrogen Vehicle Myths

Find out why hydrogen vehicles have the potential to reshape the global transportation economy, and why common misinformation about the technology isn’t backed up by the facts.

Building Mission-Critical Hydrogen Compressors

Learn why one pioneering hydrogen compressors manufacturer relies on Swagelok for high-quality fluid system solutions to propel the burgeoning hydrogen mobility marketplace.

Specifying High Performance CNG/LNG Fittings

Compressed natural gas (CNG) and liquefied natural gas (LNG) transportation applications require high-performance tube fittings that meet a number of important criteria. Learn what makes for an ideal CNG fitting or LNG fitting.

The Anatomy of a Hydrogen Fitting

Learn why fittings designed specifically for hydrogen applications can help fuel cell vehicle OEMs and infrastructure developers achieve safer and more reliable fuel systems.

Exploring Earth’s Secrets with Offshore Drilling

Japanese Deep-Sea Scientific Drilling Vessel Chikyu collects scientific data from deep below the ocean floor. Find out why researchers trust Swagelok for reliable fluid system performance and support.

On the Frontier of Hydrogen Transportation

Find out how advanced fitting technology helps the Swiss government improve hydrogen fuel cell vehicles and promote clean mobility.

Building Reliable Compressed Natural Gas Stations

CNG vehicles are increasingly common and require reliable refueling infrastructure. Learn three ways to build safer, more reliable CNG refueling stations.

Sourcing High Quality CNG Fuel System Components

Find out what to consider when selecting and sourcing critical fuel system components for compressed natural gas (CNG) vehicles, equipment, and infrastructure.

Optimizing Hose Selection for Tire Curing Presses

Find out how Swagelok can help tire manufacturers optimize hose selection for curing presses, driving greater productivity and safety while eliminating downtime.

Combating Common Fluid System Leaks in Tire Facilities

Tire manufacturers can grow accustomed to leaking process pipes, but system leaks can pose significant safety hazards and drain profitability. Learn how to identify common leak sources throughout a plant and how to fix them.

Critical Components for Forward-Thinking Fuel Systems

Swagelok and bus manufacturer New Flyer have worked together for years to develop reliable alternative fuel systems for forward thinking transit applications.

Optimizing Component Selection for Hydrogen Fuel Cell Vehicles

Hydrogen transportation depends on reliable component specification and selection. Learn more from Swagelok.

Case Study: Swagelok Helps Green Alternative Systems Control Labor Costs with Tube Bending Solutions

With Swagelok’s help testing ways to control labor costs, Green Alternative Systems (GAS) experienced a 75% reduction in production time – which translated into $224,000 in annual labor savings. Read more about how the collaboration paid off.

Luxfer Hydrogen Fuel Cell Case Study

Swagelok’s spirit of collaboration and willingness to invest in an EC-79 certification enabled Luxfer to create fuel delivery systems to power 144 hydrogen fuel cell buses. Learn how Swagelok Manchester’s level of commitment drove innovation for Luxfer.

Meeting the Needs of Hydrogen Vehicles and Zero-Emissions Technology at ACT Expo

Clean transportation is important, and hydrogen vehicles require reliable infrastructure to become more viable and widespread.

Lightfoot Defence Case Study

Lightfoot Defence, a leader in military refrigeration technology, worked with Swagelok to develop innovative solutions for the Eurofighter unified jet. Learn how Swagelok fluid system components were used to create high-tech refrigerant equipment for Lightfoot.

Swagelok Enables STEM Project-Based Learning

Through the sponsorship of BLOODHOUND SSC, Swagelok is enabling STEM learning opportunities for Hudson City School District. Discover how Swagelok is helping inspire the next generation of engineers and scientists with project-based learning.

Fluid System Evaluation and Advisory Services

How Analytical Accuracy Saved Two Major Refiners Millions

Gasoline blending operations can generate significant unnecessary costs if sampling and analysis are not performed efficiently and effectively. Read how two major refiners solved time delay and accuracy issues with the help of Swagelok.

How Proper Hose Installation Can Reduce Semiconductor Fab Costs

How to reduce costs by avoiding issues like hose condensation and energy loss in semiconductor manufacturing by following proper hose installation practices.

Top 5 Hydrogen Design Best Practices

As one of the most promising sources of clean energy, hydrogen is important—but building fluid systems to handle it requires specific knowledge and expertise. Learn critical, practical tips for designing hydrogen systems.

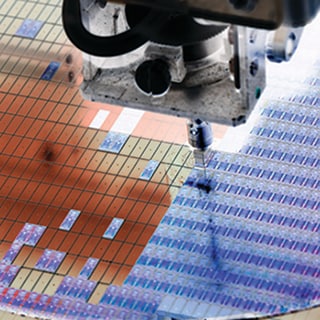

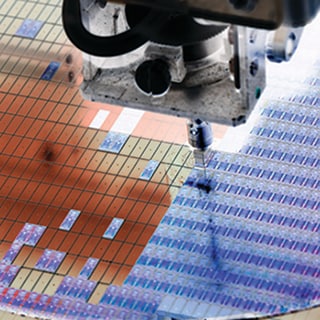

Improve Semiconductor Wafer Manufacturing Yield With Proper Thermal Control

Semiconductor wafer manufacturing requires precise process and temperature control. Learn how optimizing thermal controls throughout the semiconductor tool ecosystem can lead to less downtime, higher yields, and increased production efficiency.

Hydrogen: A Truly Sustainable Alternative Fuel

Have questions about the sustainability profile of hydrogen fuel? We have answers—learn more about hydrogen production and the fuel’s potential as a viable, sustainable power source.

Why Hydrogen Is a Cost-Effective Fuel

Is hydrogen too expensive for mass adoption as an alternative fuel? The answer is simple: No. Learn why hydrogen fuel prices continue to fall, making it a viable alternative to fossil fuels.

Have Hydrogen Vehicle Range Anxiety? Here’s Why You Shouldn’t.

Do hydrogen fuel cell vehicles have what it takes to travel comparable ranges to gasoline or diesel vehicles? We have the facts. Learn why hydrogen is a viable fuel for longer-range travel.

Is Hydrogen a Safe Fuel Source?

Hydrogen has the potential to be a revolutionary clean energy source, but some common myths abound about the fuel’s safety. Get the facts about hydrogen as we explore why it’s a safer fuel source than conventional options.

FAQs: How to Avoid Hydrogen Embrittlement

Selecting the right materials for hydrogen-handling applications is critical to the long-term viability of hydrogen as a fuel source. Learn how to select the right materials and prevent hydrogen embrittlement.

How to Decarbonize and Cut Fugitive Emissions

Refineries and oil and gas facilities face an increasing need to reduce fugitive emissions throughout their facility. Learn the driving factors behind decarbonization and fugitive emissions reduction and strategies to do it.

Optimize Your Electrolyzers With Fluid System Support

The hydrogen electrolysis process depends on reliable inflow and outflow fluid systems. Learn how you can control costs, enhance safety, and maximize productivity with the right fluid system support.

Improve Gas Distribution Safety and Efficiency

Gas distribution systems are crucial for helping labs, test centers, and industrial facilities operate at peak efficiency. Learn more about optimizing gas delivery system health and safety, reducing costs, and equipping your team for success.

Seven Tips for Effective Plant Turnarounds

A plant turnaround can be a big headache for a chemical plant or refinery—but it doesn’t have to be. Learn seven strategies for more effective turnaround management.

Your Top Five Questions of 2022

Find answers to some of the most common questions we received throughout 2022, reflected in the most popular Swagelok Reference Point posts of the year. We cover droop in flow curves, industrial hose best practices, and more.

Common Causes and Costs of Fluid System Leaks

The smallest leak can present a serious issue when maintaining your plant’s safety and profitability. Understand how and why leaks occur, how to locate and test for them, and ultimately how to develop a strategy to address and reduce leaks plant-wide.

Supporting the Production and Storage of Green Hydrogen

See how Everfuel is making hydrogen happen with the help of Swagelok products and expertise.

How to Optimize Semiconductor ALD Processes

Learn why specialized valves and a well-designed valve control system can enable more efficient and reliable atomic layer processes and provide semiconductor manufacturers new tools for process optimization.

Your Industrial Fluid System Safety Checklist

Follow these best practices to enhance the safety of your industrial fluid system.

Q&A: How to Optimize Your Gas Distribution System

Learn about common challenges that can hamper the safety and efficiency of important gas distribution systems and how a professional evaluation of those systems can provide long-term value.

Building Mission-Critical Hydrogen Compressors

Learn why one pioneering hydrogen compressors manufacturer relies on Swagelok for high-quality fluid system solutions to propel the burgeoning hydrogen mobility marketplace.

Everything You Need to Know About Pressure Regulators

Learn everything you need to know about pressure regulators with this complete guide from Swagelok. Optimize your pressure control for safer, more reliable operations.

Why Fast Support Matters for Semiconductor Fabs

Reducing total cost of ownership for semiconductor fabs is possible by working with suppliers that can provide fast, local support for critical challenges. Find out how Swagelok can help.

Five Reasons to Take Advantage of Virtual Training

With travel and visitor restrictions in place, a leading Australian gas supplier turned to Swagelok to provide essential tube fitting and installation training in a virtual format. Find out the top five benefits the company has reported so far.

2020 Blogs in Review

Discover our most popular blog posts of the year, covering everything from hydrogen transportation to grab sampling, based on the most pressing questions that our customers asked us throughout 2020.

Gas Plant Saves 90% on Labor, Eliminates Leaks

Leveraging years of experience and specialized equipment, Swagelok Calgary helped a major natural gas processor expedite its leak detection process, achieving a 90% reduction in required labor, among other benefits.

Field Engineering Spotlight: Trey Sinkfield

Swagelok field engineers work to help customers solve tough fluid system challenges. Hear from Swagelok Southeast Texas’ Trey Sinkfield on why he loves working collaboratively with customers to find effective fluid system solutions.

Identifying Cost Savings in Utility Gas Systems

See how Swagelok Texas Mid-Coast provided on-site analyses of a major petrochemical producer’s aging utility gas system and uncovered savings of more than $2 million annually.

Field Engineering Spotlight: Alex Chu, Engineering Manager, Swagelok Bristol

Engineering Manager Alex Chu helps his customers tackle challenges by understanding their needs and requirements. Learn how Alex and the Swagelok Bristol and Swagelok Isle of Man teams applied their fluid system expertise to develop ventilators to aid the U.K.’s coronavirus response.

Combating Common Fluid System Leaks in Tire Facilities

Tire manufacturers can grow accustomed to leaking process pipes, but system leaks can pose significant safety hazards and drain profitability. Learn how to identify common leak sources throughout a plant and how to fix them.

Industrial Virtual Visits: A New Form of “On-Site Experience”

Learn how Swagelok is adopting virtual headset technology to provide real-time troubleshooting, fluid system evaluation services, and more to customers when in-person visits are difficult to arrange.

Field Engineering Spotlight: Q&A with Andrew Wright

Andrew Wright is a Swagelok field engineer who enjoys being on site helping customers solve their fluid system challenges. From identifying common issues to designing custom solutions, Andrew answers the call anytime problems arise.

Field Engineering Spotlight: Mike Strobel

Swagelok field engineer Mike Strobel uses his expertise to help customers solve tough challenges. Find out how in this new Field Engineering Spotlight.

Tackling Practical Performance Issues in Fluid and Sampling Systems

Learn practical tips on how to improve the performance and accuracy of your fluid and sampling systems from Swagelok.

Boost Quality by Selecting the Right Grab Sampling System

Learn how to select the right grab sampling system and other grab sampling basics and best practices to ensure end product quality from Swagelok.

Field Engineering Spotlight: Alice Chin

South East Asia Field Engineering Supervisor Alice Chin helps customers solve tough fluid system challenges. Learn more about Alice in this Field Engineering Spotlight.

Fluid System Training: Is Your Trainer Trained?

Fluid system training is critical in oil and gas applications around the world. Learn more about how to evaluate the right training opportunities from Swagelok.

Swagelok Field Engineer Services: Improving Analytical Instrumentation

Worldwide, industrial facilities are feeling the pressure to increase profits despite the widening manufacturing skills gap. Swagelok field engineers can help remedy your fluid system challenges with training and expert evaluation services.

Four Ways Training and Advisory Services Can Help You Bridge the Skills Gap

Learn how fluid system training and advisory services can help operators bridge a growing skills gap across several industries.

In Case You Missed It: Our Five Most Popular Blog Posts of 2019

Which topics drew the most attention this year on the Swagelok Reference Point blog? Find out here, and catch up on any popular posts you missed.

Speeding the Production of Catalyst Testing Systems for Integrated Lab Solutions

Learn how Swagelok’s solutions-driven associates and quality fluid system components helped speed the production of catalyst testing systems for Integrated Lab Solutions, a Berlin-based manufacturer of automated testing equipment.

How to Improve Fluid System Performance

When fluid systems fail to perform safely and efficiently, plant productivity suffers. Swagelok can relieve the pressure of maintaining good system performance by providing expert guidance and helping to create a culture of continuous improvement.

Field Engineering Q&A: What to Know for Better Fluid and Sampling System Performance

Swagelok Field Engineering Services can help fluid and sampling system operators solve issues from leaks to sampling inaccuracy and everything in between. Here’s everything you need to know about Swagelok Field Engineering.

Steam Heat Exchangers and Tracing Systems: Best Practices for Design Engineers

When selecting heat exchanger and tracing components for steam systems, it’s necessary design engineers understand the system’s operational characteristics and requirements. Review Swagelok’s best practices to enhance your facility’s steam system.

7 Tips for Building Safer Industrial Fluid Systems

When designing industrial fluid systems, plant safety must always remain top of mind. Learn how your team of engineers and technicians can reduce safety risks and maintain system uptime with essential fluid system building and design tips.

How an Industrial Hose Maintenance Plan Could Save Your Plant Thousands

Knowing the proper time to replace your industrial hoses can save your plant thousands in maintenance costs. Learn how to evaluate your systems and develop a preventive maintenance plan to manage the health of your hoses.

3 Steps to Hose Safety & Lower Plant Costs

Industrial hose safety is often deprioritized during regular plant maintenance. It is important hoses receive the attention they deserve—leaks and wear can put your facility at risk. Learn tips to avoid dangerous situations while lowering plant costs.

Maximizing the Life of Industrial Fluid System Components

The cost of replacing an industrial fluid system component goes beyond the price of the part. Learn how to lower system costs while maximizing the life of your components with preventive maintenance tips from the professionals at Swagelok.

Closing the Manufacturing Skills Gap: 3 Steps to a Well-Trained Team

With an aging industrial workforce nearing retirement, manufacturers are turning to younger generations to replace expert knowledge. Learn how to build an effective fluid system training program with expert advice from Swagelok.

4 Strategies to Maximize Industrial Fluid System Efficiencies

Like most plant managers and engineers, you have a lot of responsibilities—but not all the resources you need to run your plant safely and efficiently. Learn how to maximize throughput, reduce costs and avoid downtime while managing your fluid system.

Global Construction

Improving Operations with JIP33 Gas Fitting Standards

Avoid costly delays and ensure compliance with JIP33 gas fitting specifications. Learn how standardization improves safety, reliability, and project performance.

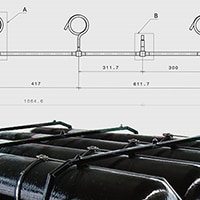

Tackling the Complexities of FPSO Builds

Learn the considerations that should be made when undertaking the construction of a new floating production storage and offloading (FPSO) vessel, and how the right fluid systems supplier can help.

Building More Profitable Semiconductor Fabs

Learn why choosing high-quality fluid system parts and assemblies can contribute to faster semiconductor fabrication facility construction, and lower total cost of ownership over the facility’s lifetime.

Standardizing Fluid System Components on Megaprojects

Swagelok’s global construction services can help oil and gas owner operators realize major operational benefits by standardizing fluid system components used across the site. Learn more about the advantages of standardization.

Grab Sampling in Global Industrial Construction

Global construction is complex, and grab sampling is often overlooked. See how to apply best practices to ensure samples meeting quality, safety, and environmental goals.

Tackling Global Engineering Complexity for a Successful Megaproject

Swagelok’s Global Construction team worked closely with dozens of global engineering firms to complete a massive petrochemical megaproject in Southeast Asia. Learn about the keys to this successful project.

Learn How We Support the Oil and Gas Industry

Collaborative Success on an FPSO Rectification

Helping an FPSO operator address widespread corrosion and small‑bore tubing failures by delivering a turnkey engineering solution ranging from design and fabrication to technical mentoring and rapid problem solving.

North Sea Gas Field Operations Success

Read how Swagelok supported a North Sea gas project with technical oversight and installation guidance, helping ensure safe operations, reduced rework, and timely delivery in a challenging offshore environment.

Improving Operations with JIP33 Gas Fitting Standards

Avoid costly delays and ensure compliance with JIP33 gas fitting specifications. Learn how standardization improves safety, reliability, and project performance.

How Analytical Accuracy Saved Two Major Refiners Millions

Gasoline blending operations can generate significant unnecessary costs if sampling and analysis are not performed efficiently and effectively. Read how two major refiners solved time delay and accuracy issues with the help of Swagelok.

Tackling the Complexities of FPSO Builds

Learn the considerations that should be made when undertaking the construction of a new floating production storage and offloading (FPSO) vessel, and how the right fluid systems supplier can help.

Ask Swagelok: Hydrogen, Sampling and Corrosion Insights

Explore expert insights on fluid systems with Swagelok's video series. Topics include hydrogen design and embrittlement, offshore corrosion, liquid sampling and more.

Know Your Process Analyzers: Raman Analyzers

Learn about Raman process analyzers, including their advantages and ideal applications, and why accurate process analysis can help you reduce off-spec products.

How to Safely Sample High-Viscosity Fluids in Refineries

Bitumen sampling poses some inherent challenges not found in other sampling applications. Learn some of the considerations that should be made when sampling bitumen or other high-viscosity fluids and liquids.

Why Fluid System Filters Are Critical for Reliable Operations

Learn about the basics of fluid system filters and gas and liquid filtration as well as how you can apply them to your systems to protect critical components and optimal outcomes.

How Training Can Minimize Risk on Oil and Gas Platforms

Proper training on critical fluid system activities is important on oil and gas platforms. Learn how the right training can help prevent accidents.

Material Matters: Selecting the Right Material for Corrosion Resistance

An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections. No wonder choosing corrosion-resistant material isn’t easy. Learn how to make choices right for your application.

Optimizing Medium-Pressure Oil and Gas Applications with Compression Fittings

For medium-pressure applications in oil and gas topside assets, the speed and performance benefits of compression fittings can make all the difference.

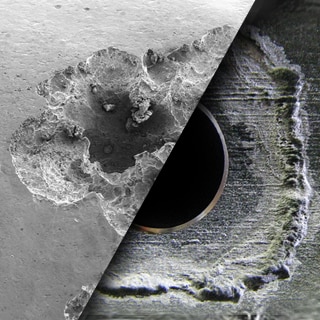

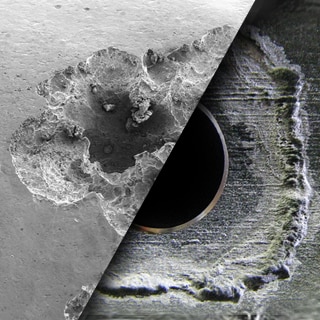

Pitting Corrosion vs. Crevice Corrosion: Identifying the Differences

Stainless steel corrosion in tubing systems is a leading cause of profit loss for oil and gas companies every year. Learn how to identify & combat two main types of corrosion, pitting corrosion and crevice corrosion, with tips from Swagelok experts.

3 Reasons to Audit Your Offshore Fluid System

Evaluation and advisory services for your offshore platform can reveal hidden leaks or other potential safety and performance issues.

Swagelok & HOERBIGER Collaborate to Reduce NOx Emissions on Legacy Engines

The collaboration between Swagelok Custom Solutions and HOERBIGER Engineering Services (HES) has been a successful one, resulting in better performing parts and lower labor costs for HES’s retrofit projects.

Standardizing Fluid System Components on Megaprojects

Swagelok’s global construction services can help oil and gas owner operators realize major operational benefits by standardizing fluid system components used across the site. Learn more about the advantages of standardization.

Choosing the Right Type of Pressure Regulator for Your Application

Learn how to match the right type of industrial pressure regulator to specialized applications, helping you best maintain process conditions to improve operational safety and efficiency.

Our Most Popular Blogs in 2021

Read our most popular blog posts of 2021, which cover your most pressing challenges, from corrosion control to fitting selection to material specification.

Tube Fitting Spec Update: Improving Safety and Performance

Learn why newly specified attributes for oil and gas tubing and tube fittings can help improve safety and system performance in platforms around the world.

Employing Medium-Pressure Ball Valves for Offshore HPUs

See how Ocean Edge Services used FKB series ball valves by Swagelok to engineer hydraulic power units (HPUs) that are ruggedly built for the people who do the work.

Exploring Earth’s Secrets with Offshore Drilling

Japanese Deep-Sea Scientific Drilling Vessel Chikyu collects scientific data from deep below the ocean floor. Find out why researchers trust Swagelok for reliable fluid system performance and support.

Enhance Safety and Save with Optimized Materials

Discover how offshore platform owners can optimize their material selection for tube and tube fittings to control costs and enhance safety in a variety of applications.

Ensuring Reliable Deepwater Well Operations with Custom Solutions

As depths get deeper and pressures grow higher, deepwater oil wells demand the ultimate in fluid system performance. Learn why a major oil well operator has trusted Swagelok for high-quality, customized solutions since 2013.

4 Answers on Material Selection for Sour Oil and Gas Fields

As oil and gas production expands into sour environments high in hydrogen sulfide, material reliability becomes critical. Learn how proper material selection and adherence to NACE standards can keep your system running efficiently.

Why Materials Science Training Matters to Oil and Gas Instrumentation Engineers

Fluid system training is critical in oil and gas applications around the world. Learn more about how technical trainings can make a difference for your facility.

Thermal Relief Valves Systems from Swagelok Speed Production for Charbonneau Industries

Learn how Swagelok Custom Solutions helped Charbonneau Industries focus on their core capabilities by speeding production, reducing labor costs and securing system quality with prefabricated thermal relief valves systems.

Products and Assemblies

What Are PFAS?

Learn what PFAS are, why they’re under scrutiny, how Swagelok avoids restricted PFAS chemicals and offers PFAS‑free materials when appropriate for non‑essential uses.

Improve Safety and Efficiency in Liquid Grab Sampling

Learn about safe and effective liquid grab sampling techniques, as well as ideal design characteristics to seek out when selecting and specifying your systems and panels.

How to Select Valves for Industrial Fluid Systems

Learn how to apply the practical STAMPED method to select the valves most suited to your industrial fluid or sampling system design applications.

How to Choose a Regulator

Learn the differences between common types of pressure regulators for industrial fluid and analytical systems, as well as how to choose a regulator most appropriate for your system needs.

Key Differences in Small-Bore Fittings

Learn the key differences between commonly available tube fitting types used in a variety of applications in this handy introduction to small-bore fittings.

Optimizing Medium-Pressure Oil and Gas Applications with Compression Fittings

For medium-pressure applications in oil and gas topside assets, the speed and performance benefits of compression fittings can make all the difference.

How to Avoid System Leaks: The Importance of Proper Tube Preparation

A successful tube fitting depends on many criteria, but one of the most important is proper tube preparation before installation. Learn to avoid costly or dangerous leaks by avoiding damaged, burred, or improperly cut tubes.

Small Footprint, Large Impact: How to Detect and Protect Against Gauge Failures

Learn to recognize the signs of a failing gauge and avoid risk to employees and costly downtime to make repairs.

Specifying High Performance CNG/LNG Fittings

Compressed natural gas (CNG) and liquefied natural gas (LNG) transportation applications require high-performance tube fittings that meet a number of important criteria. Learn what makes for an ideal CNG fitting or LNG fitting.

Swagelok & HOERBIGER Collaborate to Reduce NOx Emissions on Legacy Engines

The collaboration between Swagelok Custom Solutions and HOERBIGER Engineering Services (HES) has been a successful one, resulting in better performing parts and lower labor costs for HES’s retrofit projects.

Building Better Mechanical Seal Support Systems

Learn how API 682 guides the design and assembly of mechanical seal support systems and how applying a few best practices can help your systems last longer and work better.

The Anatomy of a Hydrogen Fitting

Learn why fittings designed specifically for hydrogen applications can help fuel cell vehicle OEMs and infrastructure developers achieve safer and more reliable fuel systems.

When to Bend Tubing—And How to Do It Right

Discover the applications where bent tubing is advantageous over pipe and fitting connections, as well as what skills and equipment are required to bend tubing for your fluid systems.

Why Safe Industrial Pressure Regulator Performance Requires Rigorous Testing

Learn why robust pressure regulator testing can help verify proof of performance under the most strenuous, real-world industrial fluid system applications.

Valves 101: What Fluid System Pros Should Know

Industrial valves play an important role in controlling the flow of media in critical fluid systems. Learn more about valve types, their functions, and how to make the right selection.

On the Frontier of Hydrogen Transportation

Find out how advanced fitting technology helps the Swiss government improve hydrogen fuel cell vehicles and promote clean mobility.

An Introduction to Fittings: Identifying Thread Size and Pitch

Learn how to determine thread size and pitch for fittings in your small-bore industrial fluid system using the right tools, decreasing the chance of leaks or blowouts.

Gas Delivery Knowledge Supports a Critical Cause

Learn how Swagelok engineers leveraged their knowledge in gas delivery and distribution to develop medical ventilators to aid in the event of a shortage during the COVID-19 pandemic.

Managing Supply Pressure Effect (SPE) in a Regulator

Supply pressure effect, also known as dependency, is an inverse relationship between inlet and outlet pressure variables within a regulator. Learn how to manage this phenomenon in your pressure regulators with tips from Swagelok.

Cut Maintenance Costs with Enhanced Gas Panels

Learn how easy-to-use gas panels and an overall more efficient gas distribution and delivery system can help laboratories, refineries, and other facilities drive down maintenance costs.

Inventory and Innovation at a Carbon Capture Company

Learn how LanzaTech, a carbon capture technology company, stays ahead of shifting customer needs and continuously innovates with high quality products, services, and inventory solutions from Swagelok.

How to Improve Your Maintenance Program with Valve and Hose Tags

Hear from two Swagelok specialists how a robust tagging system for hoses and valves throughout your industrial fluid systems can help you simplify maintenance and minimize system downtime.

2020 Blogs in Review

Discover our most popular blog posts of the year, covering everything from hydrogen transportation to grab sampling, based on the most pressing questions that our customers asked us throughout 2020.

Improving Output Quality and Production Efficiency

Since the 1980s, Rosendahl Nextrom has depended on Swagelok to move its business forward. Learn more about the solutions that allowed the company to outpace its competitors and remain an industry leader.

Enhance Safety and Save with Optimized Materials

Discover how offshore platform owners can optimize their material selection for tube and tube fittings to control costs and enhance safety in a variety of applications.

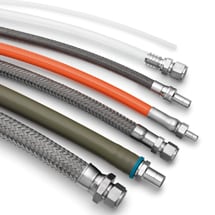

How to Select the Right Hose Reinforcement

Industrial hoses typically contain critical reinforcement layers that contribute to longevity and performance. Learn about different reinforcement layers types and which is best suited for different fluid system applications.

Sourcing High Quality CNG Fuel System Components

Find out what to consider when selecting and sourcing critical fuel system components for compressed natural gas (CNG) vehicles, equipment, and infrastructure.

Fluid Systems for the Scientific Frontier

Learn why Finnish dilution refrigerator manufacturer Bluefors trusts Swagelok for fluid system components and solutions that help enable quantum computing, experimental physics and more.

Optimizing Hose Selection for Tire Curing Presses

Find out how Swagelok can help tire manufacturers optimize hose selection for curing presses, driving greater productivity and safety while eliminating downtime.

How Shenyang Blower Works Group Improved Safety and Reliability

Learn how Swagelok Shanghai has helped Shenyang Blower Works Group Corporation achieve consistency, reliability, and cost savings for its customers while improving its own safety and production efficiency.

Field Engineering Spotlight: Alex Chu, Engineering Manager, Swagelok Bristol

Engineering Manager Alex Chu helps his customers tackle challenges by understanding their needs and requirements. Learn how Alex and the Swagelok Bristol and Swagelok Isle of Man teams applied their fluid system expertise to develop ventilators to aid the U.K.’s coronavirus response.

Ensuring Reliable Deepwater Well Operations with Custom Solutions

As depths get deeper and pressures grow higher, deepwater oil wells demand the ultimate in fluid system performance. Learn why a major oil well operator has trusted Swagelok for high-quality, customized solutions since 2013.

Q&A: Semiconductor Manufacturing Past, Present, and Future

Find out how collaboration between semiconductor tool OEMs, microchip manufacturers, and fluid system solutions providers has enabled the semiconductor market to keep up with the demands of Moore’s Law for decades, and where we go from here.

Solving Semiconductor Fabrication Challenges with Insulated Hoses

The right insulated hose solution can help solve some common challenges associated with the highly precise semiconductor fabrication process.

Field Engineering Spotlight: Q&A with Andrew Wright

Andrew Wright is a Swagelok field engineer who enjoys being on site helping customers solve their fluid system challenges. From identifying common issues to designing custom solutions, Andrew answers the call anytime problems arise.

Optimizing Component Selection for Hydrogen Fuel Cell Vehicles

Hydrogen transportation depends on reliable component specification and selection. Learn more from Swagelok.

Boost Quality by Selecting the Right Grab Sampling System

Learn how to select the right grab sampling system and other grab sampling basics and best practices to ensure end product quality from Swagelok.

Tackling Practical Performance Issues in Fluid and Sampling Systems

Learn practical tips on how to improve the performance and accuracy of your fluid and sampling systems from Swagelok.

Speeding the Production of Catalyst Testing Systems for Integrated Lab Solutions

Learn how Swagelok’s solutions-driven associates and quality fluid system components helped speed the production of catalyst testing systems for Integrated Lab Solutions, a Berlin-based manufacturer of automated testing equipment.

How Fluid System Fabrication Can Alleviate Resource Constraints

There are several common fluid systems that successful plant operations depend on, and choosing the right fabrication provider can be highly beneficial if you’re short on resources.

Case Study: Swagelok Helps Green Alternative Systems Control Labor Costs with Tube Bending Solutions

With Swagelok’s help testing ways to control labor costs, Green Alternative Systems (GAS) experienced a 75% reduction in production time – which translated into $224,000 in annual labor savings. Read more about how the collaboration paid off.

Sample Probe, Calibration & Switching Modules + More to Simplify Sampling

Learn how standard pre-engineered subsystems can bring efficiency and consistency to your operations by reducing the manual installation and assembly of multiple parts.

Thermal Relief Valves Systems from Swagelok Speed Production for Charbonneau Industries

Learn how Swagelok Custom Solutions helped Charbonneau Industries focus on their core capabilities by speeding production, reducing labor costs and securing system quality with prefabricated thermal relief valves systems.

Luxfer Hydrogen Fuel Cell Case Study

Swagelok’s spirit of collaboration and willingness to invest in an EC-79 certification enabled Luxfer to create fuel delivery systems to power 144 hydrogen fuel cell buses. Learn how Swagelok Manchester’s level of commitment drove innovation for Luxfer.

Process Measurement – Impulse Line Best Practices

It can be difficult to identify issues within your process instrumentation application if you focus solely on the transmitter. Learn how to solve problems within your process instrumentation line with tips and best practices from Swagelok.

Industrial Hose Replacement: Core Tube Material

When selecting an industrial hose, the first place to start is the core tube—the hose’s innermost layer. Learn how to select the ideal hose for your application with information on core tube materials & wall construction from the experts at Swagelok.

Meeting the Needs of Hydrogen Vehicles and Zero-Emissions Technology at ACT Expo

Clean transportation is important, and hydrogen vehicles require reliable infrastructure to become more viable and widespread.

How to Position Nozzles in Your Liquid & Natural Gas Sampling System

The details can make all the difference in sampling system efficiency. Avoid analysis delays, sample contamination, & inaccurate results in your liquid or gas sampling system by adhering to these nozzle placement best practices from Swagelok analytical instrumentation expert Karim Mahraz.

Lightfoot Defence Case Study

Lightfoot Defence, a leader in military refrigeration technology, worked with Swagelok to develop innovative solutions for the Eurofighter unified jet. Learn how Swagelok fluid system components were used to create high-tech refrigerant equipment for Lightfoot.

How to Calibrate an Analyzer in an Analytical Instrumentation System

Calibration is an important process and an absolute requirement in analytical systems. Care must be taken when performing this process—error can be introduced. Learn how to calibrate your analyzer to ensure an accurate analytical measurement.

How to Isolate Industrial Fluid Systems with Block Valves

The isolation of industrial fluid system lines prior to maintenance is vital to plant safety. One of the safest ways to isolate a fluid system line is to install two block valves. Learn how to design proper configurations for your system.

Safety

What Are PFAS?

Learn what PFAS are, why they’re under scrutiny, how Swagelok avoids restricted PFAS chemicals and offers PFAS‑free materials when appropriate for non‑essential uses.

Why You Should Not Intermix Tube Fittings

Learn why intermixing and interchanging tube fittings and tube fitting components from different manufacturers can lead to potentially poor performance in your industrial fluid or analytical instrumentation system.

How to Install Tube Fittings

Learn how to install tube fittings using the proper fitting installation techniques in order to improve facility safety, reliability, and profitability.

How Training Can Minimize Risk on Oil and Gas Platforms

Proper training on critical fluid system activities is important on oil and gas platforms. Learn how the right training can help prevent accidents.

Common Causes and Costs of Fluid System Leaks

The smallest leak can present a serious issue when maintaining your plant’s safety and profitability. Understand how and why leaks occur, how to locate and test for them, and ultimately how to develop a strategy to address and reduce leaks plant-wide.

Your Guide to Valve Maintenance and Troubleshooting

Valves are critical to safe and reliable fluid system operation. Learn to maintain and troubleshoot valves in this guide.

Why Relief Valves Are Essential for Chemical Plant Safety

Learn how to improve chemical plant safety and protect sensitive equipment by designing relief valves into critical applications to prevent potentially dangerous overpressurization.

What to Look for in Hydrogen Valves

Valves are critical parts of hydrogen fluid systems. Learn what to look for in an ideal hydrogen valve and how it can contribute to safer, more reliable hydrogen transportation.

The Benefits of On-Site Field Engineering Support

Find out how Swagelok’s on-site field engineering services can benefit your existing or new fab semiconductor chip manufacturing operations.

Building Safe and Reliable Hydrogen Refueling Stations

Learn how a leading hydrogen refueling station and onboard fuel system manufacturer in China is keeping pace with the rapidly evolving hydrogen transportation market with help from Swagelok.

Busting Hydrogen Vehicle Myths

Find out why hydrogen vehicles have the potential to reshape the global transportation economy, and why common misinformation about the technology isn’t backed up by the facts.

How to Optimize Semiconductor ALD Processes

Learn why specialized valves and a well-designed valve control system can enable more efficient and reliable atomic layer processes and provide semiconductor manufacturers new tools for process optimization.

Reviewing Flexible Hose End Connection Types & Use Cases

Learn the types of tubing or flexible hose end connections most used across industries, from pharmaceutical to semiconductor, and how to assess and select products best suited for your specific application.

Tube Cutting Tools and More: Five Tools for Fluid System Pros

From tube cutting tools to orbital welders, learn about five critical tools every fluid system professional should have by their side in any plant setting.

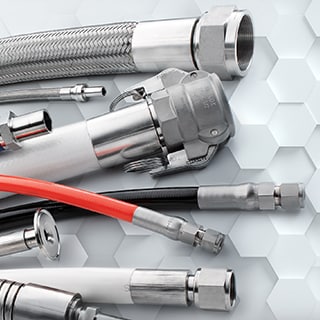

Everything You Need to Know About Industrial Hoses

Learn all about industrial hoses, including how to choose a hose, in our complete guide to hoses, end connections, core materials, and more.

Your Industrial Fluid System Safety Checklist

Follow these best practices to enhance the safety of your industrial fluid system.

3 Reasons to Audit Your Offshore Fluid System

Evaluation and advisory services for your offshore platform can reveal hidden leaks or other potential safety and performance issues.

Everything You Need to Know About Pressure Regulators

Learn everything you need to know about pressure regulators with this complete guide from Swagelok. Optimize your pressure control for safer, more reliable operations.

How to Reduce Costly Leaks and Emissions in Your Facility

Leaks can cause trouble in any process-driven industrial facility. Learn how to reduce common costly fluid system leaks, including fugitive emissions, with the right high-quality products and services.

Tube Fitting Spec Update: Improving Safety and Performance

Learn why newly specified attributes for oil and gas tubing and tube fittings can help improve safety and system performance in platforms around the world.

Grab Sampling in Global Industrial Construction

Global construction is complex, and grab sampling is often overlooked. See how to apply best practices to ensure samples meeting quality, safety, and environmental goals.

Employing Medium-Pressure Ball Valves for Offshore HPUs

See how Ocean Edge Services used FKB series ball valves by Swagelok to engineer hydraulic power units (HPUs) that are ruggedly built for the people who do the work.

Improving Lab Safety and Productivity

Learn why optimized gas distribution systems are critical for maintaining the safety and productivity of laboratories.

Gas Delivery Knowledge Supports a Critical Cause

Learn how Swagelok engineers leveraged their knowledge in gas delivery and distribution to develop medical ventilators to aid in the event of a shortage during the COVID-19 pandemic.

Building Reliable Compressed Natural Gas Stations

CNG vehicles are increasingly common and require reliable refueling infrastructure. Learn three ways to build safer, more reliable CNG refueling stations.

How to Improve Your Maintenance Program with Valve and Hose Tags

Hear from two Swagelok specialists how a robust tagging system for hoses and valves throughout your industrial fluid systems can help you simplify maintenance and minimize system downtime.

Gas Plant Saves 90% on Labor, Eliminates Leaks

Leveraging years of experience and specialized equipment, Swagelok Calgary helped a major natural gas processor expedite its leak detection process, achieving a 90% reduction in required labor, among other benefits.

Field Engineering Q&A: What to Know for Better Fluid and Sampling System Performance

Swagelok Field Engineering Services can help fluid and sampling system operators solve issues from leaks to sampling inaccuracy and everything in between. Here’s everything you need to know about Swagelok Field Engineering.

The Three T’s to Achieve an Intricate System of Tubing

Learn how the three T’s to using a hand tube bender can help you achieve an intricate system of tubing with fewer leak points and efficient flow.

Refinery Safety Depends on Well-Trained, Empowered Employees

Fugitive emissions of hazardous gases can occur in refineries. Safe, leak-free containment depends on knowledgeable and empowered teams.

INEOS Petrochemical Safety Case Study

Swagelok’s contribution to the safe operation of INEOS’s petrochemical facility in Cologne, Germany maps back to the close collaboration between the two companies. Learn how Swagelok’s trusted reliability helps INEOS ensure petrochemical safety.

How to Isolate Industrial Fluid Systems with Block Valves

The isolation of industrial fluid system lines prior to maintenance is vital to plant safety. One of the safest ways to isolate a fluid system line is to install two block valves. Learn how to design proper configurations for your system.

7 Tips for Building Safer Industrial Fluid Systems

When designing industrial fluid systems, plant safety must always remain top of mind. Learn how your team of engineers and technicians can reduce safety risks and maintain system uptime with essential fluid system building and design tips.

4 Strategies to Maximize Industrial Fluid System Efficiencies

Like most plant managers and engineers, you have a lot of responsibilities—but not all the resources you need to run your plant safely and efficiently. Learn how to maximize throughput, reduce costs and avoid downtime while managing your fluid system.

Sampling Systems

Ask Swagelok: Hydrogen, Sampling and Corrosion Insights

Explore expert insights on fluid systems with Swagelok's video series. Topics include hydrogen design and embrittlement, offshore corrosion, liquid sampling and more.

How to Achieve Safer, More Accurate, and More Efficient Ammonia Sampling

Learn how pre-engineered ammonia sampling systems can take away some of the complexity and inherent risks involved with manual ammonia sampling practices.

How to Safely Sample High-Viscosity Fluids in Refineries

Bitumen sampling poses some inherent challenges not found in other sampling applications. Learn some of the considerations that should be made when sampling bitumen or other high-viscosity fluids and liquids.

How Fluid System Fabrication Can Alleviate Resource Constraints

There are several common fluid systems that successful plant operations depend on, and choosing the right fabrication provider can be highly beneficial if you’re short on resources.

Tips for Safe, Accurate Gas Grab Sampling

Read about common challenges associated with volatile liquid and gas grab sampling and learn to overcome them by using the right techniques and appropriate equipment.

Sample Cylinder Maintenance FAQ: What You Should Know

Learn about the importance of sample cylinder maintenance for safe operations and what it takes to develop a proactive maintenance program.

Analyzing Your Sampling Needs

Trying to determine whether grab sampling or online analysis is the best option to monitor your process conditions? We put together a convenient checklist to help guide you to a solution that suits your operations.

How to Reduce Emissions at Sampling Points

As refineries, chemical plants, and other facilities seek new ways to reduce fugitive emissions, one strategy can be relatively simply and cost-effective: specifying closed-loop sampling systems.

Back-Pressure Regulator Set-Up: Tips for Sampling System Engineers

Back-pressure regulators can effectively control upstream pressure within a sampling system process line—when set up correctly. Learn how to accurately design and build a process line with a back-pressure regulator.

An Introduction to Grab Sampling

Learn about grab sampling best practices for both gaseous and liquid fluid system media, the characteristics of well-designed and easily operable grab sampling systems, and how to reliably achieve grab sampling accuracy.

How to Use a Regulator to Reduce Time Delay in an Analytical Instrumentation System

Time delay is often underestimated or misunderstood in analytical systems. One way to mitigate this delay is with a pressure-controlled regulator. Learn how manage your analytical system’s time delay with tips from the experts at Swagelok.

How Consistent Grab Sampling Enables Ongoing Innovation for a Leading Refrigerant Producer

Refrigerant and fluoropolymer production requires adherence to strict quality control measures and safety protocols. Learn how one leading manufacturer stays ahead of the competition with Swagelok grab sampling solutions.

Liquid Grab Sampling Strategies to Control Costs

Discover several strategies to help drive down costs and minimize errors in your liquid grab sampling processes as you validate process conditions and analyze end product quality.

Analytical Sampling Systems Q&A

Swagelok Field Engineering Manager Mike Frost answers questions on common analytical sampling system problems.

Five Considerations for Your Analyzer Shelter

Analyzer shelters are an important part of any industrial refinery or other oil and gas facility. Learn some fluid and sampling system concerns to think about from Swagelok.

Field Engineering Spotlight: Mike Strobel

Swagelok field engineer Mike Strobel uses his expertise to help customers solve tough challenges. Find out how in this new Field Engineering Spotlight.

3 Rules for Analyzer Accuracy

Learn to avoid three common sampling system performance problems that can lead to analyzer inaccuracies, costing you time and money.

Tackling Practical Performance Issues in Fluid and Sampling Systems

Learn practical tips on how to improve the performance and accuracy of your fluid and sampling systems from Swagelok.

Boost Quality by Selecting the Right Grab Sampling System

Learn how to select the right grab sampling system and other grab sampling basics and best practices to ensure end product quality from Swagelok.

Do’s and Don’ts for Sampling System Accuracy

Follow these do’s and don’ts to obtain more accurate, representative samples from your industrial sampling system.

How to Fix Common Grab Sampling Deficiencies

There are several common fluid systems that successful plant operation depends on and outsourcing their fabrication can be highly beneficial if you are short on resources.

Sample Probe, Calibration & Switching Modules + More to Simplify Sampling

Learn how standard pre-engineered subsystems can bring efficiency and consistency to your operations by reducing the manual installation and assembly of multiple parts.

How to Select the Right Sample Preconditioning Module

When selecting a sample preconditioning module for your sampling system, there are several factors to keep in mind to ensure sample accuracy & plant safety. Swagelok Product Manager Randy Rieken gives tips on how to choose a proper module.

How to Position Nozzles in Your Liquid & Natural Gas Sampling System

The details can make all the difference in sampling system efficiency. Avoid analysis delays, sample contamination, & inaccurate results in your liquid or gas sampling system by adhering to these nozzle placement best practices from Swagelok analytical instrumentation expert Karim Mahraz.

Using a Phase Diagram for Vapor Pressure Curves

In this article, Swagelok’s Karim Mahraz gives detailed instructions covering how to use a phase diagram for vaporization management. Plant managers and design engineers can use phase diagrams to determine & refine inputs during gas sample analysis.

Why Haven’t Sampling Systems Improved — Three Main Reasons

Over the past 50 years, process analyzers have vastly improved— but sampling systems have not. Luckily, most issues are due to human error & can be corrected with proper training. Learn three reasons why sampling systems fail & solutions for your plant.

Avoiding Classic Liquid and Gas Sampling System Mistakes

Whether you’re working with a gas or a liquid sample, common sampling system mistakes often occur during initial design. Learn how to avoid classic sampling mistakes and get better gas and liquid samples every time with design tips from Swagelok.

Grab Sampling 101: Reducing Plant Costs

Grab sample systems allow for safe, efficient sample captures—validating your product’s chemical composition. Learn how to improve your closed loop system’s reliability while reducing plant costs with basics from the experts at Swagelok.

Common Challenges with Process Sampling Systems

Sampling system experts and industry veterans, Tony Waters and Phil Harris, share some common challenges they have encountered with process analyzer sampling systems over the years. Learn how to resolve recurring issues within your sampling system.

How to Manage Vaporization in Sampling Systems

It’s not easy to vaporize a sample, nor is it always possible. Learn how to better understand the vaporization process in an analytical system and how to manipulate variables— ensuring proper vaporization for an accurate sample.

4 Areas to Inspect When Measuring Time Delay in Sampling Systems

In a process analyzer sampling system, there is always a time delay before you obtain a reading. However, underestimating this time delay can lead to inferior process control. Learn which four areas you should closely inspect to diminish time delays.

Tips to Maintaining a Representative Sample in an Analytical Instrumentation System

Maintaining a representative sample within an analytical instrumentation system can be difficult. Learn how to identify major issues and avoid complications associated with a compromised representative sample from the experts at Swagelok.

Calculating the ROI of Process Analyzer Technology

Process analyzers are a costly, but necessary, sampling system expenditure. When justifying this expense, it’s important that you accurately calculate the analyzer’s ROI. Learn how to determine ROI and save your plant money with tips from Swagelok.

Understanding and Measuring Time Delay in an Analytical Instrumentation System

Process measurements are instantaneous, but analyzer responses are not. Time delay in sampling systems is the most common cause of inaccurate results from process analyzers. Learn how to understand and reduce time delay in your analytical systems.

Sampling Systems: 8 Common Process Analyzer Accuracy Challenges

Sampling systems expert and veteran industry instructor Tony Waters offers plant managers and design engineers tested ways to identify and resolve 8 common challenges for process analyzer accuracy.

10 Tips to Improve Sampling Systems

Managing an analytical instrumentation operation is no small feat. Receiving consistent results can be a struggle for even the most seasoned engineers. Luckily, there are several simple tips your team can use to improve your sampling system.

Semiconductor

How Proper Hose Installation Can Reduce Semiconductor Fab Costs

How to reduce costs by avoiding issues like hose condensation and energy loss in semiconductor manufacturing by following proper hose installation practices.

Improve Semiconductor Wafer Manufacturing Yield With Proper Thermal Control

Semiconductor wafer manufacturing requires precise process and temperature control. Learn how optimizing thermal controls throughout the semiconductor tool ecosystem can lead to less downtime, higher yields, and increased production efficiency.

Optimize These Applications for More Profitable Semiconductor Fabs

As semiconductor fab construction booms around the world, manufacturers should consider how optimizing critical industrial fluid system applications can contribute to more efficient and profitable operations.

The Benefits of On-Site Field Engineering Support

Find out how Swagelok’s on-site field engineering services can benefit your existing or new fab semiconductor chip manufacturing operations.

How to Optimize Semiconductor ALD Processes

Learn why specialized valves and a well-designed valve control system can enable more efficient and reliable atomic layer processes and provide semiconductor manufacturers new tools for process optimization.

How to Solve Top ALD and ALE Semiconductor Processing Challenges

ALD and ALE semiconductor production processes come with some inherent challenges and complexities. Learn how the right selection of process valves can help you overcome them.

Building More Profitable Semiconductor Fabs

Learn why choosing high-quality fluid system parts and assemblies can contribute to faster semiconductor fabrication facility construction, and lower total cost of ownership over the facility’s lifetime.

Vacuum Face Seal Fittings Explained

Learn why vacuum face seal fittings represent an ideal solution for uncompromising ultrahigh-purity semiconductor fluid system applications.

Why Fast Support Matters for Semiconductor Fabs

Reducing total cost of ownership for semiconductor fabs is possible by working with suppliers that can provide fast, local support for critical challenges. Find out how Swagelok can help.

Improve Semiconductor Yield with Optimized Alloys

Discover how semiconductor fabricators can improve end-to-end production yields and improve long-term profitability by selecting the right metals for critical fluid system components.

Q&A: Semiconductor Manufacturing Past, Present, and Future

Find out how collaboration between semiconductor tool OEMs, microchip manufacturers, and fluid system solutions providers has enabled the semiconductor market to keep up with the demands of Moore’s Law for decades, and where we go from here.

Solving Semiconductor Fabrication Challenges with Insulated Hoses

The right insulated hose solution can help solve some common challenges associated with the highly precise semiconductor fabrication process.

One New Valve. Three Reasons It Could Change Semiconductor Manufacturing

Find out how the latest innovation in atomic layer deposition (ALD) valve technology is changing the game for high-tech semiconductor manufacturers.