Why You Should Avoid “Compatible” Tube Fitting Intermix

Why You Should Not Intermix or Interchange Tube Fittings from Different Manufacturers

One way to prevent these issues is to build your fluid systems with tube fittings from a single manufacturer. Claims that tube fitting components can be intermixed and interchanged with those of different manufacturers should be questioned. There are no products from other manufacturers that are proven to be Swagelok-compatible. It can be not only costly, but risky to intermix brands or interchange brands of fittings as it may compromise worker safety by introducing unnecessary risk into system operation.

Do you or your installers regularly intermix or interchange tube fittings based on claims that other manufacturers’ fittings, nuts, or ferrules are Swagelok-compatible? If so, read on to learn the reasons why tube fitting intermix and tube fitting interchange can lead to poor fluid system performance.

What Is Tube Fitting Intermix and Tube Fitting Interchange?

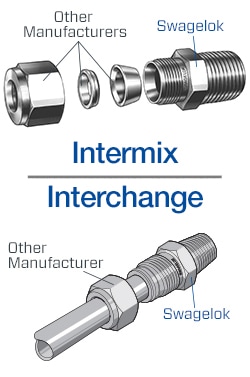

Intermix is when tube fitting components, including the nuts, ferrules, and bodies from two or more manufacturers are mixed together and then assembled to make a completed fitting. For example, if Swagelok tube bodies are combined with internal components from other manufacturers that are positioned as “Swagelok-compatible,” this would be an instance of intermix.

Interchange is when a tube fitting from one manufacturer (e.g., Swagelok) that has been installed on a piece of tubing is then disassembled, and the tubing, nut, and ferrules are then reassembled into a tube fitting body from another manufacturer (e.g., a Swagelok alternative).

Why Intermix and Interchange Can Become Problematic

One of the most important reasons to avoid brand intermix and interchange is because there is no industrywide commercial design standard for tube fittings. This means that every individual manufacturer follows its own design standards and processes, which can result in differences ranging from incremental to significant.

No manufacturer can reliably and uniformly replicate designs from that of a competitor, and any resulting failure will certainly void any short-term savings. Tube fitting components from different manufacturers are not explicitly designed to work together. Thus, an intermixed or interchanged fitting is essentially a new, untested design. Even if components look similar, they could vary more imperceptibly due to due to differences in material composition, electroplating, or surface hardening.

An intermixed or interchanged fitting is essentially a new, untested design.

Intermixed or interchanged fittings may result in:

- Inconsistent or incompatible sealing surfaces due to differences in design, geometry, tolerances, and material properties

- Reduced sealing effectiveness from mismatched swaging mechanisms and torque requirements

- Compromised performance and increased risk of fatigue failure

For these reasons, interchanging and intermixing tube fitting components can lead to unpredictable performance, increased costs, and potential safety hazards. Intermix and interchange may also void your warranty. For example, fittings intermix and interchange will void Swagelok’s Limited Lifetime Warranty, regardless of whether alternative components are labeled as “Swagelok-compatible,” resulting in even higher costs if and when a problem occurs.

What Brands are Swagelok-Compatible?

There is No “Swagelok-compatible” alternative. Some manufacturers may claim that their products are interchangeable with other brands (e.g., Swagelok-compatible). Manufacturers making these claims typically say that doing so can help save an operator on costs, but there is no “Swagelok equivalent” or “Swagelok alternative,” for example, that will provide the same performance as an actual Swagelok® tube fitting.

Always Avoid Tube Fitting Intermix and Interchange

Avoiding intermix and interchange is a best practice promoted by numerous fluid systems standards agencies. For example, the IOGP JIP-33, an initiative aimed at making dramatic improvements in the specification, procurement and delivery of oil and gas equipment, specifically calls tube fitting intermix and interchange a “bad engineering practice.”

Single-sourcing your tube fittings from one reliable supplier is a good way to avoid potential interchange and intermix, even by accident. When only one brand is available, technicians cannot mistakenly combine components from two different manufacturers.

You can read more about key differences between fittings in this article. Interested in learning more about important design and construction best practices for your critical fluid systems? Our engineering specialists offer a wide variety of services to optimize operations, whether you need help diagnosing problems, designing a new assembly, or training your workforce.

Related Articles

Reducing Costly Fluid System Leaks and Emissions

Leaks can cause trouble in any process-driven industrial facility. Learn how to reduce common costly fluid system leaks, including fugitive emissions, with the right high-quality products and services.

Seven Tips for Effective Plant Turnarounds

A plant turnaround can be a big headache for a chemical plant or refinery—but it doesn’t have to be. Learn seven strategies for more effective turnaround management.

Do’s and Don’ts for Sampling System Accuracy

Follow these do’s and don’ts to obtain more accurate, representative samples from your industrial sampling system.