Jump to Section:

Start Every Day With a Clean Sheet

- The reliability of our valves and fittings can help pulp and paper mills reduce emissions, maintain compliance with environmental regulations, and earn government rebates

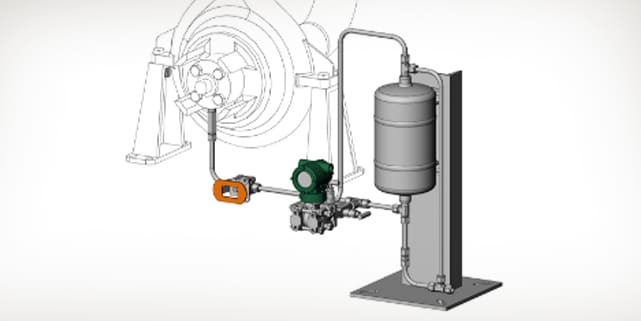

- Our fluid control components used in steam systems and for condensate return contribute significantly to leak-tight performance and energy savings

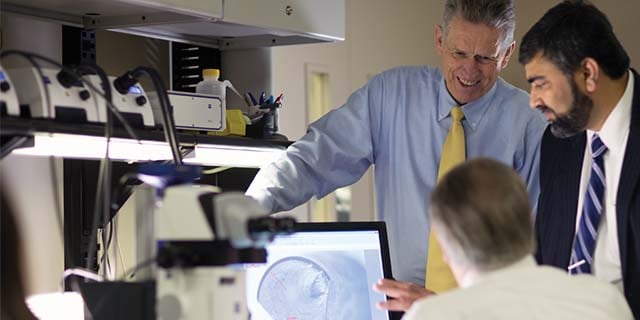

- We also provide consultation, engineering assistance, as well as training, all to equip your team with the skills to work safely and efficiently

- Site evaluations and advisory services can further reduce the potential for costly leak detection and repair (LDAR) procedures

We know the challenges that steam, chemicals, temperature, and vibration place on machines and instrumentation. Our solutions-first approach helps you stay in step with changing Technical Association for the Pulp, Paper and Converting Industry (TAPPI) standards for ISO quality management, manufacturing standardization, and workplace health and safety.

Pulp and paper manufacturers worldwide trust Swagelok to perform under pressure and help them responsibly meet production goals without sacrificing speed or quality.

Pulp and Paper Applications

Our expertise extends to virtually all equipment and process support systems found in pulp and paper mills, plants, and facilities including:

- Agitators

- Cleaning machines

- Coaters

- Compressed air systems

- Deflakers

- De-inkers

- Dispersion systems

- Dryers

- Forming (Fourdrinier) machines

- Finishing equipment

- Headbox units

- Hydraulic systems

- Lubricating systems

- Paper-making machines

- Presses

- Pulpers

- Reject handlers

- Steam systems

- Stock preparation machines

- Suction rolls

- Thickeners

- Wastewater filtration systems

Products for Pulp and Paper

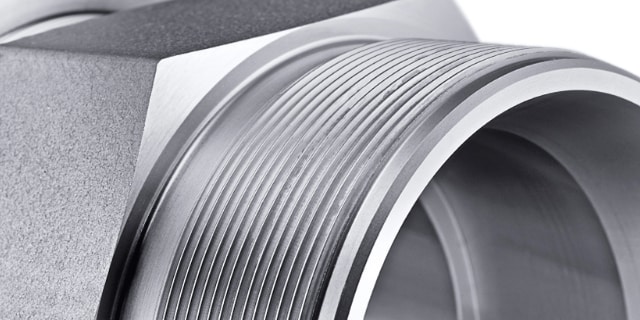

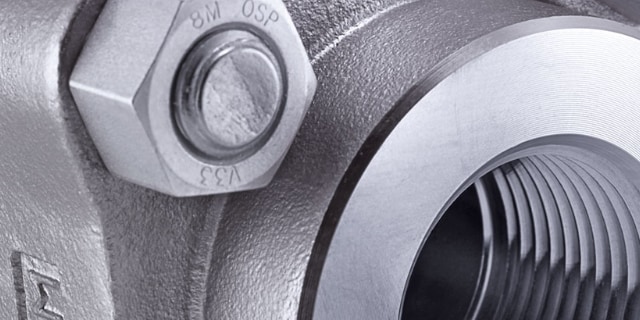

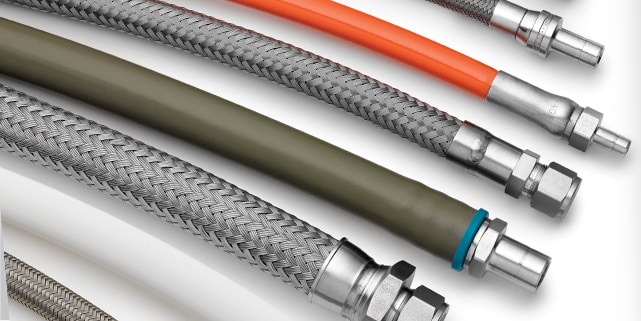

To meet stringent demands in a variety of pulp and paper industry applications, we offer a complete line of fluid system components, including reliable fittings, valves, and hose products that are backed by the Swagelok® Limited Lifetime Warranty.