Jump to Section:

Solutions for Everything That Moves Your Business

We know what is needed to take the pressure off plant managers, QA engineers, and others who manufacture, maintain, or operate industrial machines and equipment. That includes:

- More knowledge about effective solutions for minimizing harsh vibration and mechanical stresses in critical fluid systems

- More standard and custom product options so that production lines do not come to a halt and service stays on schedule

- More safety and dependability designed into all types of applications that require a specialist’s touch

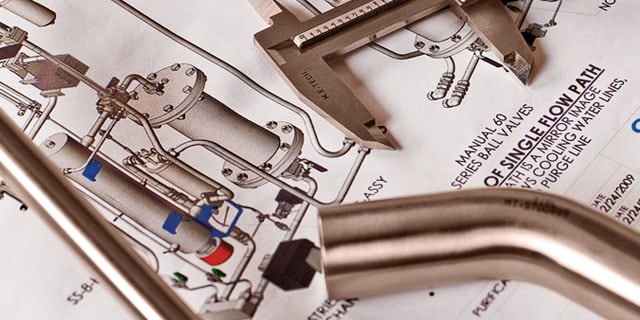

We can help you design, build, install, and optimize everything that moves your business forward. With 200-plus authorized Swagelok sales and service center (SSC) locations worldwide, professional assistance is always easy to find.

Industrial Machinery and Equipment Applications

With a broad scope of fluid system products and an extensive knowledge of industrial machine design, we can support all types of connection and joining needs including for:

- Automation and assembly equipment

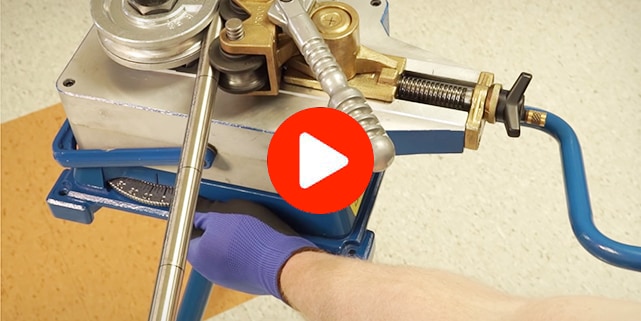

- Bending machines

- Compressors and test devices

- Electromechanical challenges

- Fuel cell applications

- Heat exchangers

- Hydraulic equipment

- Injection molding machines

- Pneumatic equipment

- Presses and pumps

- Refrigeration systems

- Rolling mills

- Thermal and heat exchange devices

- Various accessory equipment

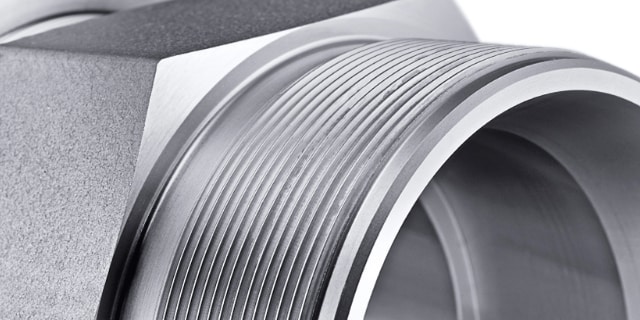

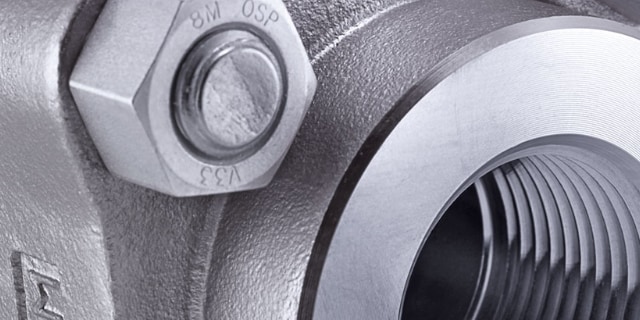

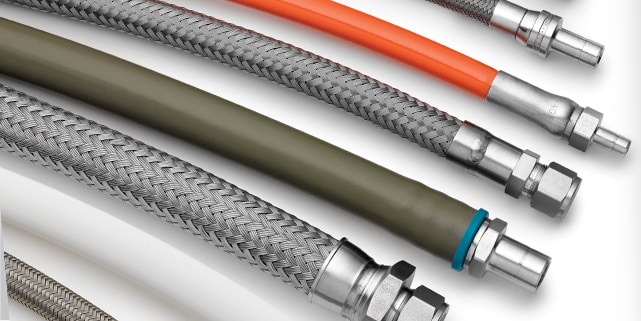

Products for Industrial Machinery and Equipment

All fluid system products from Swagelok are intended to enable the highest level of application, process, and instrumentation integrity throughout your plant, in your service facility, or from the machines that you build. Backed by our transferrable Limited Lifetime Warranty that follows your equipment, each component is the result of more than 75 years of engineering excellence. Solutions designed to keep industrial machines in motion while keeping people safe include: