Measuring and Controlling Hydrogen Flow

Measuring and Controlling Hydrogen Flow

As clean and plentiful as that resource is, however, it can also be challenging to manage. Extremely small hydrogen molecules can escape the tiniest of seal imperfections and permeate solid metals, which can result in reduced ductility, and, in extreme cases, material failures. Containing this versatile gas requires highly engineered equipment and expertise. Because of this, any widespread transition to hydrogen fuel will require reliable testing technologies for the hydrogen fuel cells that will power that transition.

A Solution in the Making

A Solution in the Making

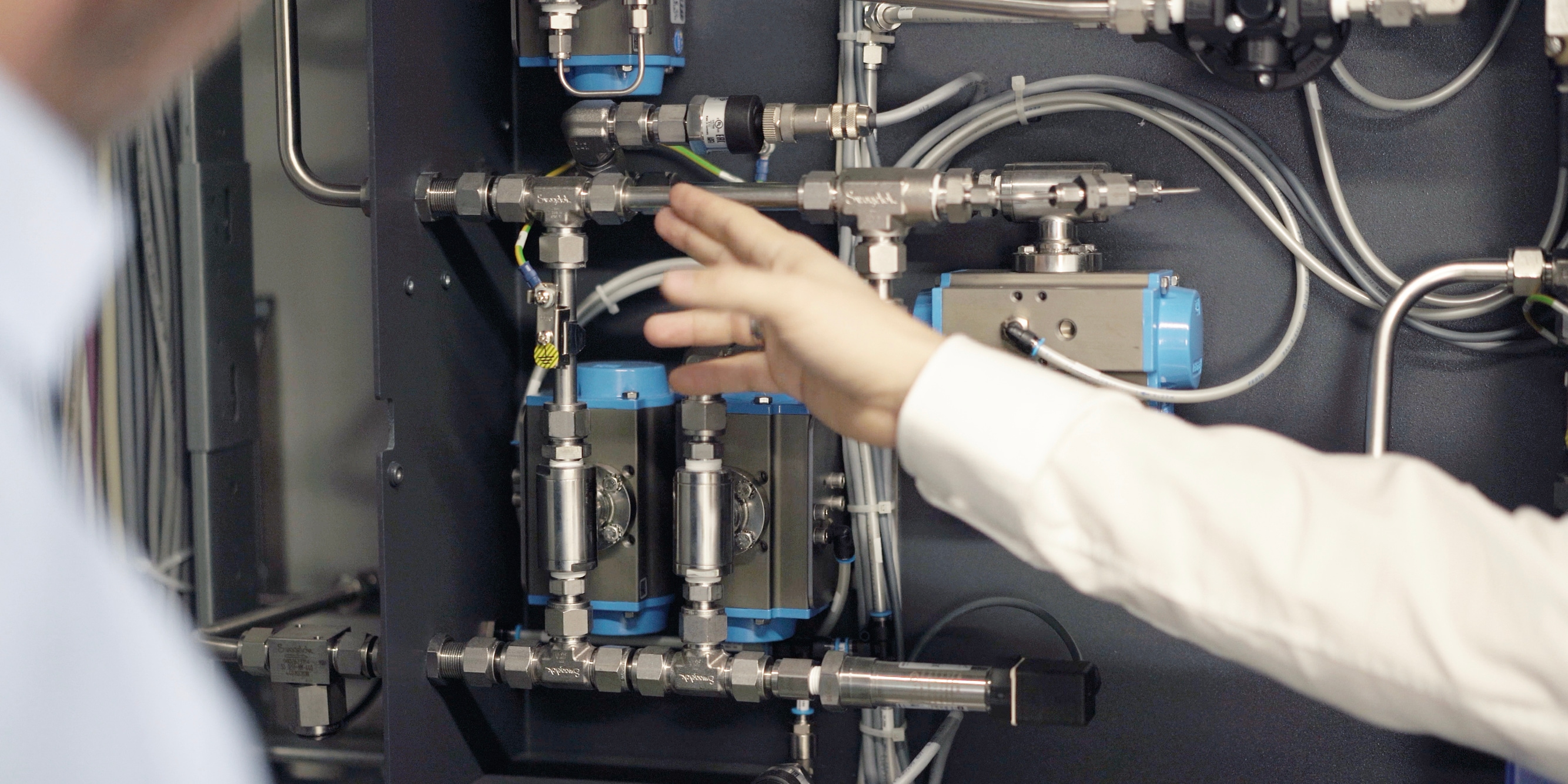

For the last three years, AVL, the world's largest independent company for testing and simulation in the automotive industry, has been making a strong push to develop that technology with AVL HyTronTM, the hydrogen consumption measuring device. The Austrian company is pioneering hydrogen fuel cell testing equipment that emulates the behavior of a real hydrogen fuel tank to mimic real conditions on the testbed. The equipment is also resistant to hydrogen embrittlement, provides flow at the correct pressure, and prevents leaks that could contaminate the stack catalyst.

For efficiency or certification tasks, HyTron provides precise hydrogen flow measurement during transient and stationary testing and an accurate, reliable, and measurable supply of hydrogen vital to fuel cell system testing and development. It must also have a flow range meeting the required gas pressure at the anode, and cannot contain any materials that could emit contaminants that would influence the stack catalyst. And, if the unit-under-test (UUT) is undergoing modifications or repairs, the supply line needs to be purged with an inert gas such as nitrogen to ensure 24/7 safe, degradation-free operation.

A New Industry Standard

A New Industry Standard

HyTron represents a shift for a company with a long history of providing testing equipment exclusively for diesel/petrol fuel OEMs. And it's already raising the bar for hydrogen measurement. “AVL HyTron was developed in a very, very short time and already has become an industry standard for the supply of hydrogen and the measurement of hydrogen consumption,” says Gerald Sommer, Global Segment Manager for AVL's Business Segment, Advanced Measurement Technologies.

“Our customers, who are major OEMs around the world, are faced with the challenge of converting their conventional combustion engine test benches to operate with hydrogen,” says David Bischof, Product Manager for HyTron. “Safety, i.e. the avoidance of gaseous, explosive chemicals, is the top priority. On the other hand, the reproducible hydrogen consumption measurement is extremely important to be able to validate and certify the entire system of hydrogen, combustion engine, or fuel cell. Our AVL HyTron is exactly the solution for this. It is the industrialized and integrated solution for the secure gas supply for development activities on the test bench with integrated consumption measurement.”

Swagelok: A Trusted Partner

Swagelok: A Trusted Partner

According to AVL, their transition to hydrogen fuels technology has been made easier through a partnership with Swagelok Austria. “Swagelok is our trusted partner in the area of hydrogen and hydrogen-compatible components,” says Sommer. “We have trust in the partnership based on the expertise that Swagelok (Austria) has.” Bischof adds: “Especially with regard to product quality, we have had extremely good experiences with the Swagelok components. It is extremely important for us to have the connection point under control so as not to risk a leak in a remote test bench at a customer.”

“What sets Swagelok apart from others is really the know-how in the field of hydrogen and the TÜV-certified measurement results,” says Thomas Rothlaender, Development Project Manager at AVL, primarily responsible for HyTron measuring devices. While AVL and Swagelok Austria have a lot in common, including a long history and shared values and approach to business, the key component in the relationship has been trust based on mutual understanding, common goals, and shared expertise. “AVL trusts Swagelok Austria. And AVL trusts the product of Swagelok itself. The tube fitting in our hydrogen application supplies a leak-tight seal which is absolutely critical for the safety of the system and the safety of the employees.”

“From our point of view,” says Rothlaender, “it is extremely important to us that the device is and remains sealed. Because we are mainly fighting misconceptions around the world about hydrogen. And the worst thing that can happen to us globally right now in terms of hydrogen is that there are accidents somewhere. That makes it more important that we deliver tight systems and show our customers and thus the world that hydrogen is known to work well, and is no more dangerous than petrol or diesel, which each of us uses every day. At that time, Swagelok was actually the only supplier who could already show TÜV certificates that could guarantee us, especially with hydrogen.”

“What sets Swagelok apart from others is really the know-how in the field of hydrogen and the TÜV-certified measurement results.”

Thomas Rothlaender

Development Project Manager, AVL

Swagelok Austria helped AVL select the right material and supply the needed certifications—especially critical for the automotive industry—as well as the different tube fittings that might be used. “Certification is always a big issue when working for the automotive industry,” says Sebastian Preiss, Area Sales Manager, Swagelok Austria. “There are several certifications required, for example, ATEX or maybe 3.1 certifications, so that you can clarify what material you use for your hydrogen system. Especially for using hydrogen, our material, 316 stainless steel is ideal.”

Quality Components and Training to Manage Them

Quality Components and Training to Manage Them

Beyond actual components, Swagelok Austria also provided critical training to help AVL’s team learn how to manage their hydrogen fluid systems. “We did a lot of training,” says Preiss, “including the Swagelok Safety Seminar, which is quite important for the handling of the Swagelok® tube fitting, especially when you use hydrogen.” Says Rothlaender, “It was important to us that our production team is adequately trained. This gives them and us the security that we are building devices that are tight from the start, if possible, that pass the tests right from the start.” And according to Bischof, “The training courses that Swagelok offers were also a great advantage in bringing Swagelok's know-how into our production. How connection technology is optimally used to avoid leakage.”

For AVL, the partnership with Swagelok Austria has added productivity and efficiency to the HyTron project. Says Rothlaender, “We simply know that we have a partner here who has provided us with consistently good quality over the past few years and who understands the subject of hydrogen – who understands that hydrogen is something different than any other gas. We actually felt supported right from the start, both in terms of know-how and the components. You can tell that Swagelok is not working with hydrogen for the first time. And we have definitely benefited from that.”

“The training courses that Swagelok offers were also a great advantage in bringing Swagelok's know-how into our production. How connection technology is optimally used to avoid leakage.”

David Bischof

Product Manager, AVL

And as clean, renewable hydrogen fuel becomes a bigger part of the global energy equation, this type of experience and expertise will help it to be safer and more efficient.

Related Articles

Building Safe and Reliable Hydrogen Refueling Stations

Learn how a leading hydrogen refueling station and onboard fuel system manufacturer in China is keeping pace with the rapidly evolving hydrogen transportation market with help from Swagelok.

Supporting the Production and Storage of Green Hydrogen

See how Everfuel is making hydrogen happen with the help of Swagelok products and expertise.

What to Look for in Hydrogen Valves

Valves are critical parts of hydrogen fluid systems. Learn what to look for in an ideal hydrogen valve and how it can contribute to safer, more reliable hydrogen transportation.