Chemical & Refining Tubing System Training

The Swagelok® Tubing System Training Program, Chemical and Refining

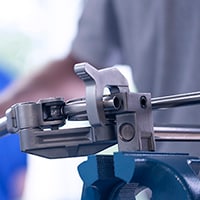

The Swagelok® Tubing System Training Program, Chemical and Refining is a globally standardized two-day workshop designed to address the small-bore tubing training needs for midstream and downstream applications. It covers tube fitting installation, inspection, tube bending, and other relevant topics.

About the Course

Topics

This training program is designed to provide knowledge and understanding of:

- Tube Selection, Installation and Routing

- Tube Preparation

- Tube Fitting Installation

- Leakage & Safety Considerations

- Taper & Straight Thread Installation

- Plugs, Caps & Tube Adapters

- MHSU Operation & Maintenance

- Hand Tube Bender, Bending Methods & Offset Bends

- Bench Top Tube Bending

- Tube Fitting Installation Inspection

- Visual Inspection, Troubleshooting & Fault Identification

- Inspection Practical Exercise

Target Audience

This hands-on training is ideal for installers, engineers, designers, QC/QA inspectors, and others responsible for designing, installing, maintaining, and/or inspecting tubing systems in midstream and downstream chemical and refining applications.

Course Format

The training provides theoretical and practical experience through a combination of explanation, demonstration, hands-on exercises, and validation. All attendees receive a Swagelok® Tube Fitter’s Installer’s Guide, Hand Tube Bender manual, and gap inspection gauge for 1/4-inch (6mm), 3/8-inch, and 1/2-inch (12 mm) tube fitting sizes. A Swagelok certificate of completion will be awarded to attendees, subject to successful completion of both practical and theoretical exam. The certificate is valid for three years.

The program addresses common concerns that are root causes for project overruns, including:

- Leaks on tube fittings and threaded connections due to incorrect installation

- Improper tube preparation

- Undertightened fittings

- Intermix and Interchange

- Tube blowout

- Contamination

- Thread galling

- Crossed threads

- Surface finish damage

- Vibration issues

- Poor tubing layout

- Improperly supported tubing

- Bend defects and bend radius interference

Course Duration

Two (2) days in-person.

Instructor

This course is facilitated by a Swagelok-certified subject matter expert.

Swagelok Advantage

Swagelok trainers know precisely what it takes to meet tubing and fitting regulatory compliance in chemical and refining applications. Learn practical knowledge in the classroom so that your team can use their skills to solve challenges in the field.

How to Register

Sign up below for tubing system training. Your local authorized Swagelok sales and service center will follow up with full details.