Your Trusted Resource in Oil, Gas, and Chemical Refinery Services

Your Trusted Resource in Oil, Gas, and Chemical Refinery Services

At Swagelok, we understand the unique challenges you face with downstream refining. Our mission is to help you optimize your instrumentation, process control, and sampling systems.

Since 1947, we’ve delivered high-quality fluid system components that have helped leaders in the oil and gas industry minimize downtime, maximize production efficiency, and meet strict emissions standards. Our products are backed by the Swagelok Limited Lifetime Warranty and supported by a global network of authorized sales and service centers.

Solutions for Your Most Demanding Refinery Operations

Your refinery relies on a series of complex, interconnected processes to convert crude oil into valuable products. We deliver robust, leak-tight fluid system solutions and expert support to help you maximize refinery safety, reliability, and efficiency in the following key applications:

-

Crude Distillation:

We support your primary and vacuum distillation units with sampling systems, process instrumentation, and corrosion-resistant components that ensure accurate separation and protect downstream assets from impurities and fouling -

Hydrocracking:

Our solutions help you optimize hydrocracking units, where heavy gas oils are converted into high-value distillates like diesel and gasoline. Swagelok provides sample conditioning systems, grab sampling systems, and mechanical seal support systems to maintain catalyst integrity, prevent hydrogen leaks, and ensure precise process control—even under high pressure and temperature conditions. -

Fluid Catalytic Cracking (FCC):

For FCC units that break down heavy hydrocarbons into lighter products, we offer sample points, process instrumentation assemblies, and emission monitoring systems. This helps you maintain optimal reaction conditions, monitor catalyst performance, and comply with environmental regulations. -

Alkylation:

For your alkylation units that produce high-octane gasoline components, we supply corrosion-resistant valves, hoses, and tubing designed for both sulfuric and hydrofluoric acid service, supporting safe, reliable operation in these highly corrosive environments. -

Reforming and Isomerization:

For reformers and isomerization units, we deliver sampling systems and process instrumentation assemblies that help you monitor product quality, manage catalyst health, and maintain consistent reactor temperatures—ensuring your gasoline meets stringent octane requirements -

Coking and Deasphalting:

Our grab sampling systems and process instrumentation enable safe, accurate sampling of high-viscosity fluids and residuals in coking and deasphalting units, supporting efficient conversion of heavy fractions into lighter products and minimizing waste -

Sulfur Recovery:

We support your sulfur recovery units with reliable sampling and monitoring solutions for hydrogen sulfide, sulfur dioxide, and elemental sulfur, helping you meet emissions targets and maintain safe operations

Across all these applications, Swagelok professionals work with you to design, assemble, and maintain fluid systems that withstand the rigors of refining—delivering the performance, compliance, and peace of mind you need to keep your plant running at its best.

NACE Compliance and Corrosion Protection within Refinery Operations

Corrosion is a persistent and costly challenge in refining, especially when processing sour crude oil and operating under high-pressure, high-temperature conditions. According to the Association for Materials Protection and Performance (AMPP, formerly NACE), corrosion costs industries worldwide $2.5 trillion annually. We tackle this challenge head-on with our engineering expertise and NACE-compliant solutions.

At Swagelok, we design and manufacture valves, fittings, and assemblies that meet the rigorous requirements of NACE MR0175 and MR0103 standards. These standards are essential for applications where sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC) threaten the integrity of your systems—such as units handling sour crude, intermediates, or wastewater streams. Our products are engineered to withstand the harshest wet, sour environments, helping you maintain safety, reliability, and compliance throughout your operations.

Our expertise in material selection, manufacturing, and coatings allows us to address both slow-developing hydrogen-induced cracking and rapid sulfide stress cracking, protecting your assets from sudden failures and long-term degradation. Swagelok sales and service centers can help you navigate the complexities of NACE standards, providing guidance on best practices, compliance verification, and cost-effective solutions that deliver a strong return on investment.

When you trust Swagelok, you gain more than just compliant products, you gain a team dedicated to safeguarding your refinery’s performance, safety, and profitability against the risks of corrosion.

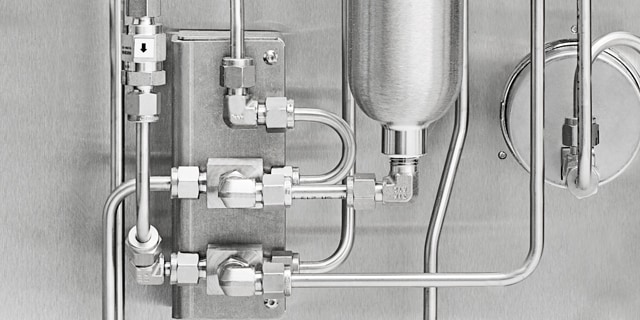

Streamline Your Operations with Swagelok Fluid System Assemblies

For decades, Swagelok has worked with customers across the world to create reliable, standardized fluid system assemblies. Our standard and configurable assemblies are built with premium components and tested under application-specific conditions, delivering exceptional performance right from the start. Pair these assemblies with our onsite services for proper installation and optimized system operation.

From grab sampling systems that provide accurate, representative samples while ensuring operator safety to mechanical seals that maintain rotating equipment and operating efficiency, we have a complete solution designed to tackle your toughest challenges. Leverage the expertise of Swagelok field engineers to transform your fluid system concept into reality—anywhere in the world. Whether your operations are local or global, we’ll help you design a system that meets regulatory requirements without sacrificing performance.

Sustainability and Environmental Impact of Downstream Refinery Solutions

At Swagelok, we recognize the importance of sustainability and environmental stewardship in today’s refining operations. Our fluid system solutions are engineered to help you reduce fugitive refinery emissions, minimize leaks, and improve energy efficiency across your facility. By providing reliable, leak-tight components and assemblies, we support your efforts to meet stringent environmental regulations and lower your carbon footprint. Additionally, our expertise in system design and training empowers your team to implement best practices for safe handling of hazardous materials and efficient resource use. With Swagelok, you can advance your sustainability goals while maintaining the performance and reliability your refinery operations demand.

We are committed to helping you achieve safe, efficient, and sustainable operations. From robust, leak-tight fluid system components and NACE-compliant solutions to expert training and support, we can deliver the reliability and expertise you need to meet the challenges of today’s refining environment. Our teams can work alongside yours to ensure every system is optimized for performance, compliance, and environmental stewardship—so you can focus on maximizing productivity and driving your business forward with confidence.

Connect with your local Swagelok refinery expert