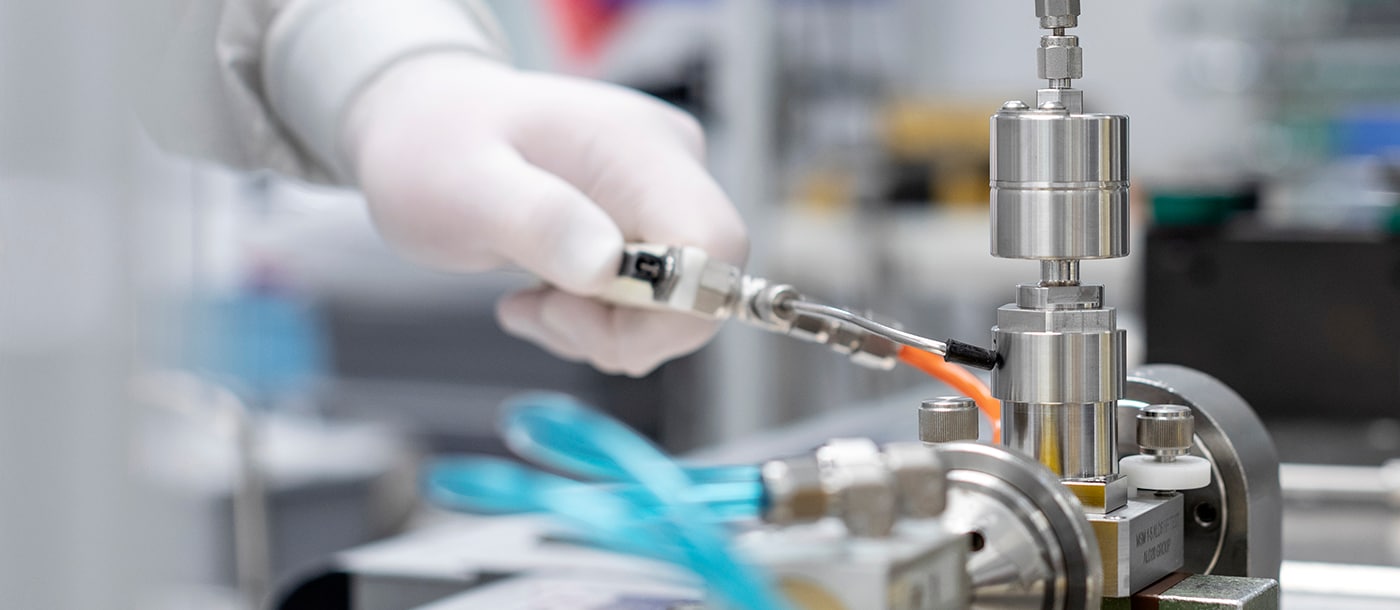

Swagelok® Atomic Layer Deposition (ALD) Valves

Swagelok ultrahigh-purity atomic layer deposition (ALD) valves offer the ultrahigh cycle life, high-speed actuation, flow rates, thermal immersibility, and extreme cleanliness needed to enable precise dosing in advanced semiconductor manufacturing applications.

Request More InformationOur high-performance ALD valves are a key example of how Swagelok has long displayed responsive technical leadership in the semiconductor manufacturing industry. Since introducing the world to ALD valve technology, Swagelok has worked closely with semiconductor industry customers to understand their needs, then create ALD valves that provide the extreme levels of precision, consistency, cleanliness, and high cycle life necessary to keep up with the quick pace of innovation in the marketplace. Our ALD ultrahigh-purity valves feature:

- Ultrahigh cycle life with high-speed actuation

- Cv range from 0.27 to 1.7

- Temperature capability up to 482°F (250°C) for specified models

- Field flow adjustability option for specified models

- Electronic or optical actuator position-sensing option

- Suitable for ultrahigh-purity applications with 316L VIM-VAR stainless steel body

- Modular surface mount, tube butt weld, and VCR® end connections

Atomic Layer Deposition (ALD) Valves Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

ALD 3, 6, and 7 Diaphragm Valves and ALD20 Bellows: Ultrahigh cycle life, high-speed actuation; Up to 392°F (200°C) w thermal actuators; Electronic actuator position-sensing; ultrahigh-purity applications; High flow capacity, PFA seat, Normally closed pneumatic actuation, Alloy 22 available

One New Valve: Three Reasons It Could Change Semiconductor Manufacturing

Find out how the latest innovation in atomic layer deposition (ALD) valve technology is changing the game for high-tech semiconductor manufacturers.

Unlock More of the Periodic TableSwagelok Resources Curated for You

Improve Semiconductor Yield with Optimized Alloys

Discover how semiconductor fabricators can improve end-to-end production yields and improve long-term profitability by selecting the right metals for critical fluid system components.

Q&A: Semiconductor Manufacturing Past, Present, and Future

Find out how collaboration between semiconductor tool OEMs, microchip manufacturers, and fluid system solutions providers has enabled the semiconductor market to keep up with the demands of Moore’s Law for decades, and where we go from here.

Fiber Optics Equipment Manufacturer Increases Efficiency with Customized Solutions

Since the 1980s, Rosendahl Nextrom has depended on Swagelok to move its business forward. Learn more about the solutions that allowed the company to outpace its competitors and remain an industry leader.

Reliable Fluid System Solutions for the Scientific Frontier

Learn why Finnish dilution refrigerator manufacturer Bluefors trusts Swagelok for fluid system components and solutions that help enable quantum computing, experimental physics, and more.