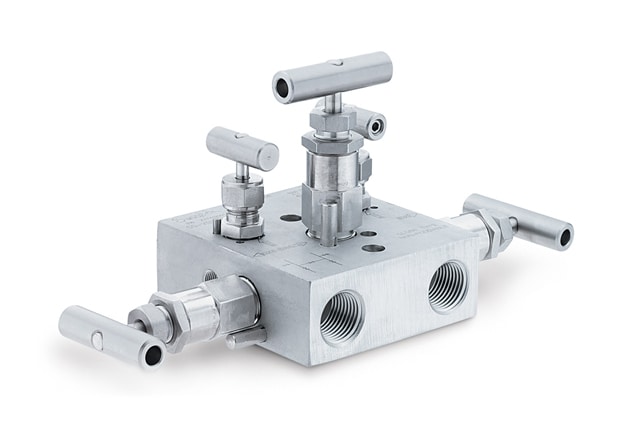

Swagelok® Manifolds

Swagelok two-, three-, four-, or five-valve manifolds are factory built and tested to deliver reliable solutions for critical instrumentation applications. Direct-mount, remote-mount, or modular systems configurations are available, including low fugitive emissions and NACE compliant alloys.

Manifolds Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

V, VB, and VL series 2-, 3-, and 5-valve instrument manifolds; VE series 2-, 3-, and 5-valve direct-mount manifolds; 2-valve remote-mount manifolds; Mod 85 modular instrumentation systems

The stream selector system is a modular assembly designed for process analyzer systems. Find technical and ordering information as well as details on atmospheric-reference and high-purge options.

The Right Valve Can Make All the Difference

Use our valve flow coefficient (Cv) calculator to chose a valve sized correctly for your needs.

Use the ToolSwagelok Resources Curated for You

How to Select the Right Valves for Your Industrial Fluid System

Learn how to apply the practical STAMPED method to select the valves most suited to your industrial fluid or sampling system design applications.

Minimize the Costs of Fugitive Emissions with Low-E Valves

Fugitive emissions are a growing concern in the chemical and petroleum refining industry. Certified low-emissions (Low-E) valves can protect your facility and bottom line. Learn what they are, how they are tested, and how they can help you in this post.

How to Isolate Industrial Fluid Systems with Block Valves

The isolation of industrial fluid system lines prior to maintenance is vital to plant safety. One of the safest ways to isolate a fluid system line is to install two block valves. Learn how to design proper configurations for your system.

One New Valve. Three Reasons It Could Change Semiconductor Manufacturing

Find out how the latest innovation in atomic layer deposition (ALD) valve technology is changing the game for high-tech semiconductor manufacturers.

Manifolds

Swagelok manifolds have fewer potential leak points by putting multiple valves in one body. They are designed for static pressure, liquid level, and differential pressure applications in traditional and compact inline body designs, for use in instrument, direct-mount, remote-mount, and module systems. The compact assembly design results in reduced size and weight and is easy to install and maintain. There are body material options such as stainless steel, carbon steel, and duplex stainless steel, and packing materials such as PTFE, for system versatility, and Grafoil®, for extended temperature ratings.