Ir a la Sección:

Aproveche al Máximo sus Sistemas de Fluidos

Además de las vibraciones y la corrosión, hay mucho que pensar a la hora de especificar los componentes y ensamblajes para las líneas de instrumentación, las necesidades de energía hidráulica, los equipos de inyección de productos químicos, los sistemas de inundación, el control continuo de las emisiones, las sondas de toma de muestras, los sistemas de acondicionamiento de muestras y otras infraestructuras de apoyo críticas.

Aquí es donde Swagelok puede ayudar.’ Cada día solucionamos los problemas de las empresas metalúrgicas y mineras de todo el mundo. Si está planeando un proyecto o necesita apoyo en el control de fluidos, cuente con nosotros para:

- Aprovechar nuestro conocimiento técnico. Colaborar con un equipo multidisciplinar de ingenieros de diseño y de campo, metalúrgicos y expertos en cumplimiento de la normativa que conocen formas más sencillas, rápidas y seguras de planificar, construir y gestionar los sistemas de fluidos.

- Una completa coordinación. Los imperativos del proyecto, las variables de ejecución y las normativas locales se irán resolviendo con un equipo de especialistas a su espalda. Planificación, diseño, logística, contratos, plazos, inventario, formación—le ayudaremos a gestionar cualquier presión a la que se enfrente.’

- Servicio post-venta. Los centros de ventas y servicio autorizados Swagelok ofrecen un nivel de apoyo excepcional durante todo el ciclo de vida de sus activos. Desde la asistencia en la planificación del mantenimiento hasta la recomendación de eficiencias y la formación de su personal, nuestro trabajo no termina hasta que el suyo lo hace.

Destacamos en la creación de conexiones fiables y en la eliminación de vacíos logísticos en cualquier proyecto de gran envergadura que abarque varios continentes. También luchamos contra la corrosión desde 1947 y podemos ayudarle a prevenir los caros problemas causados por el óxido. Consúltenos sobre las soluciones probadas de sistemas de fluidos para la extracción, el procesamiento y el refinado de minerales metálicos y reservas minerales.

Aplicaciones de Metalurgia y Minería

Apoyamos muchas de las necesidades de procesamiento de minerales y materiales auxiliares, así como las aplicaciones de planta para las empresas que extraen y tratan minerales metálicos, incluyendo:

- Tratamiento de aire/gas

- Autoclaves

- Bioprocesos

- Altos hornos

- Concentradores (flotación, deshidratación, separación magnética)

- Sistemas de Control Continuo de Emisiones (CEMS)

- Equipos de trituración, pulverización y separación

- Paneles de protección contra excesos de presión en el decantador

- Electrodepositación (electroextracción)

- Producción de electricidad

- Análisis de agua potable

- Control del nivel del tanque de reserva

- Infraestructuras de hidrógeno

- Sistemas hidrometalúrgicos (lixiviación)

- Necesidades del taller de instrumentación

- Equipos de laboratorio

- Fabricación de cal

- Líneas de lubricación

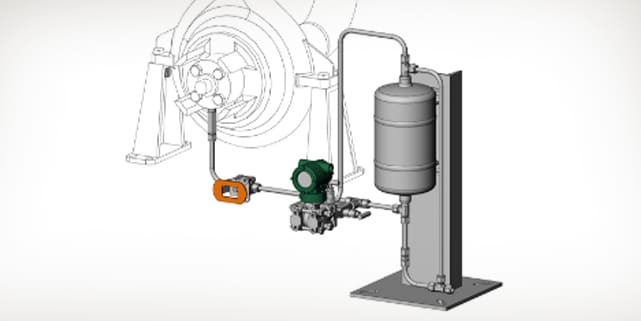

- Sistemas auxiliares al sello mecánico

- Preparación del mineral (aglomeración, filtrado, sinterizado)

- Paneles neumáticos y de instrumentación

- Trenes de laminación

- Equipos rotativos

- Fundición (operaciones pirometalúrgicas)

- Producción de acero

- Tanques de almacenamiento

- Tratamiento y desalinización del agua

Productos para la Metalurgia y Minería

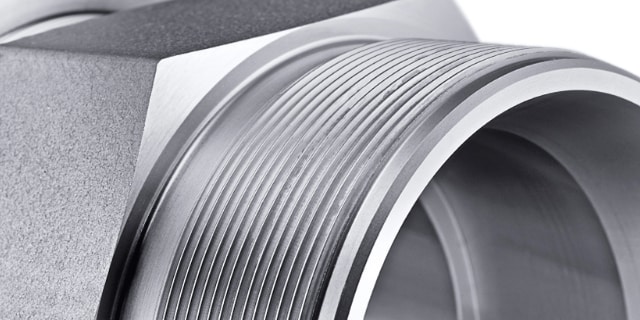

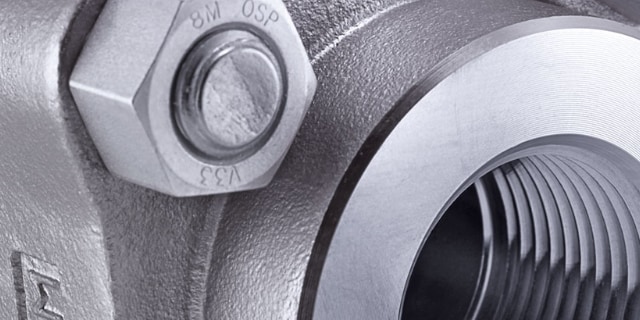

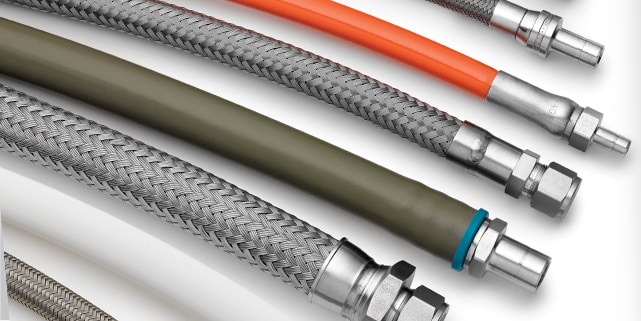

Tenemos disponible uno de los mayores inventarios para dar servicio a sus necesidades de sistemas de fluidos e instrumentación. Seleccione entre más de 290.000 variaciones de ítems acabados, con 10.500 productos almacenados en todo el mundo, disponibles en 17 aleaciones distintas, todo ello respaldado por la Garantía Limitada Vitalicia Swagelok®.