6 reasons to switch from pipe to tubing

Running pipe? Consider tubing instead!

6 reasons you should be running tubing in your facility

Written by: Greg Farley, Technical Director | February 2020

When installing or maintaining a welded, threaded or flanged piping system, consider tubing as an alternative. Despite some dated perspectives, tubing will often exceed your system pressure requirements. Properly supported tubing, will be as robust as you need it to be! With several wall thicknesses available in each size, you can be sure to find the right size tubing for your installation.

Install it faster – A properly installed tube fitting takes fractions of the time it takes to prepare pipe for the same size installation. This time savings over the course of the magnitude of a project adds up to significant savings in labor dollars!...and gets your plant up and running faster!

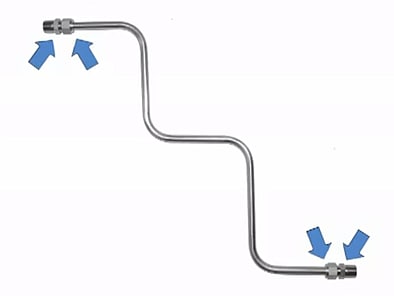

Bending tubing eliminates connections – When bending fully annealed tubing, it actually work hardens and gets stronger. By bending and routing tubing, you are eliminating unnecessary connections, saving time and materials. This also reduces the changes in the internal diameter of the line. Coupled with the radius of the bends, this improves flow and reduces turbulence!

Tubing is lighter than pipe – This better strength to weight ratio means less material to ship, store, lift, and support. This reduces the expense in shipping and eases the installation!

Tube fitting end connections on valves eliminate pipe threads – Many fluid system components such as valves, hoses, gauges, etc. are available with tube fitting end connections. These tube fitting end connections eliminate pipe threads!

Tube fittings don’t require weld permits – They don’t require fire watches either! Simple hand tools, or for 1” and larger systems, Hydraulic Swaging Units (HSU) (available for rent or purchase), are light weight and easy to use!

Less labor and less material means lower costs – Our trained Swagelok Field Engineers can collaborate with you using your labor rates to calculate the difference in total overall cost to install a tubing system versus a threaded or welded system and assist you in making the best decision for your system.

When installing or maintaining a fluid system, it's important to consider all aspects of the project. It's easy to only consider the cost of the bill of materials, but overlooking the larger expense of labor can add up quickly. A properly planned and installed tubing system can save you money! Click here to learn more, or email us at info@george.swagelok.com to request a site visit to discuss your system.